Introduction to Agarbatti making a business plan, cost, licenses, and permission: Agrabatti making is the most profitable business by using small equipment and machines; where you can start making it even at your home. Here you can find detailed information, on how to start an incense Agarbatti making business in India.

A guide to Agarbatti making a business plan, cost, licenses

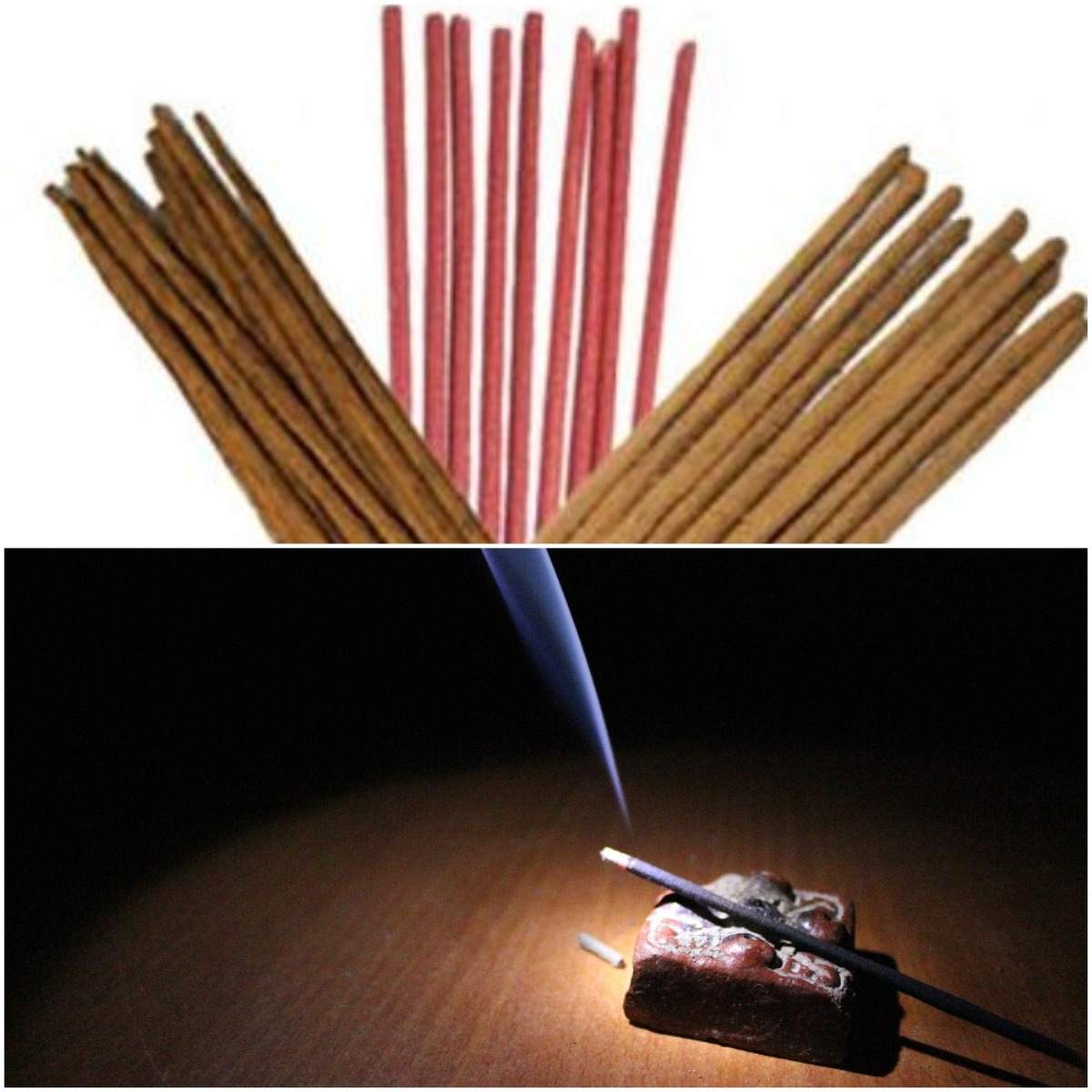

This article explains all the steps involved in total project cost, machinery, production process, sample formula, and raw materials. Asia region is the most popular region in both production and usage of the Agarbatti or incense sticks. It is a traditional product and used during daily pooja and festivals. Basically, people use Agarbatti for religious purposes and it is the essential thing in daily household activities, temples, etc.

Business plan and the steps involved in making the Agarbatti

-

Market research

Firsttly, you need to do research regarding the Agarbatti or incense sticks in India. India is one of the largest incense sticks-producing countries in the world. This product has both domestic and international demand and hence can be exported too. Karnataka stands first in producing Agarbatti, whereas South India accounts for 35% of the domestic market share. As the West-India accounts for 30%, while the North-India accounts for 18% and East India accounts for 17% respectively. Apart from this domestic consumption, it also fulfills more than half of the world’s incense sticks required. Some of the major importing countries of Agarbatti include the USA, the UK, Egypt, Nigeria, UAE, and Latin America. There are several major brands in the market that are attracting customers. However, there are few gaps for manufacturers. Some of the popular Indian Agarbatti brands include moksh, Patanjali, mangal deep, cycle, zed black, and many more.

-

Prepare the project report for Agarbatti business

Steps involved in Agarbatti making –

- Obtain Agarbatti making machines

- Obtain raw materials

- Select a suitable location and install equipment

- Staff training and appointment

- Preparation of masala or mixture

- Add mixture and bamboo sticks into equipment

- Assemble raw Agarbatti

- Dry them using a dryer or under sunlight

- Add fragrance

- Package and use it to supply

In organizing the project report, some crucial information is needed. First of all, you have to define the space for the unit and the price. As the next step, you must provide the machinery information with the quotation. And lastly, the other charges like wages for labor, raw material pricing, utility bills, etc.

You should not miss the Hand Sanitizer Making Business, License, Permission.

-

Finance for Agarbatti business

Starting an incense stick production business needs upfront start-up capital. Apart from the stable cost, you must obtain the raw materials for a certain duration without getting any monetary returns. Actually, the financial calculation will be clear by the project plan. For the project finance, the bank will ask for the owner’s share. Since we know that the equipment is available at a low price, it’s convenient to start the business with your own investment. Firstly, announce your Agarbatti brand in the market and then go for expansion. If then you need, go for the loan to your Agarbatti business.

-

Agarbatti business registration and license

Go thoroughly with the local rules and tax liabilities for this business. Apart from the old-style proprietorship or partnership establishment, you have to register your business with ROC. You need to apply for the trade license and MSME Udyog Aadhaar registration online. You should have a GST number for tax filing. If you start the unit with greater than 10 staff members, then you must check the PF and ESI act. At last, see the requirement of NOC that must be obtained from your state’s pollution control board office.

-

Setup the Agarbatti making unit

Actually, the specific condition of space is determined by the production output and the number of machines you wanted to install. However, a 1000 sq. ft covered place is sufficient for small-scale functioning and the process. Make sure the location has sufficient water supply and electrical provision. If you are not having the own location for the unit operation, it is better to opt a rented place. It will reduce the project price, hence, aids in increasing the ROI.

After finalizing the area, design the floor plan. You are required to have electrification according to the equipment positions. Basically, an effective floor design aids to enhance profits by lowering costs. For example, you must position the machines in close proximity of the raw material storage place. On the other hand, you must calculate the space for the complete goods storage place near the packaging part and exit segment.

-

Agarbatti making machine with price

In the Agarbatti business, the correct machinery choice plays a very vital role. Basically, there are three diverse types of machines that could be obtained from the market. These machines are classified as semi-automatic, manual, and fully automatic. A manual pedal type machine is most inexpensive, approximately Rs. 10,000 onwards and it consumes less electricity. But, the production output is very minimal. Hence, it is not recommended for the process. The semi-automatic machines run on electricity and are seamless for a start-up business. Actually, in a semi-automatic process, the entire machines are automatic but not connected with each other and there is a requirement of dedicated staff to constantly feed the machine with bamboo sticks. But, you will acquire a better yield from this machine type. This unit can be purchased at Rs. 5 lakh onwards.

The fully automatic systems are flawless for large-scale functioning. The fully automatic machine yields the highest amount of Agarbatti per hour. Additionally, there is no need of a dedicated person to feed the device with sticks. Hence, you can set up these machines for expansion purposes and for large-scale production. This unit could be around Rs 8 Lakh onwards.

In case if you miss this: Organic Store License and Permits, Setup Cost.

Actually, the machine cost depends on the material quality, HP, and the efficiency level. Before putting the final order, you must verify the price from the different sources. Try to purchase a machine from a closely located supplier. It will aid in having mechanical support from that supplier in the future. In the starting days, it is better to plan the project with the semi-automatic Agarbatti unit. A complete Agarbatti processing unit comprises a mixer, grinder, incense sticks vending machine, drying machine, and packaging unit. You also require wooden tables, a weighing balance, and some other equipment and hand tools.

-

Agarbatti making formula

Firstly, you can obtain the raw mix for preparing incense sticks. However, it lowers the overall profits of the unit. Basically, you must have a tailored formula as per the taste of your target demographics. A basic formula is-

- White chips 40%

- Gigatu 20%

- Charcoal 20%

- Aromatic chemical

- Essential oil and other ingredients 20%

-

Agarbatti making process

First of all, obtain the raw materials as per the fragrance you want to yield. Mix the charcoal powder, white chips, gigatu, etc. as per the formula. The next step is to mix with water to get a semi-solid paste. Take this structure on a wooden plank and add on to sticks by rolling with hands or by machine. Then raw sticks are immersed in a suitable fragrant compound diluted with white oil or other solvents like diethyl phthalate (DEP) and dried and later packed. You must have a moisture-proof packing material with a strong cardboard outer packing.

-

Raw materials required for Agarbatti making

Generally, the raw materials are easily obtainable in Asia pacific. The Agarbatti units rely heavily on forest substances for raw materials. Agarbatti manufacturing involves no specific or sophisticated materials or chemical substances.

Some of the most important components are sticky powder such as sal resin, jigat, guggul, charcoal powder, Nargis powder, water, raw bamboo sticks, various variety of oils, flower/aromatic essence, rose petals, sandalwood oil, natural and chemical aromatic components, gelatin paper, sawdust thick paper, scissor, various colour powder, waste paper, etc. also, you need a packaging material to pack your produce.

-

Best ways to sell your Agarbatti

Sell your product in the local market initially. In our country, retail dispersal is the apt way to run a business. Currently, malls, supermarkets, shopping centers, and app-based retailers are the best options for market diffusion.

The present trend also involves the sale of products from online marketplaces like Flipkart, eBay, Amazon, etc. Even exhibitions in festival season are the best locations to sell this type of product.

You may also like the How to Invest in Share Market.

TV promotion also plays an essential role in the Indian consumer market. You must add some of your hard work into the brand establishment and product promotion gradually.

Costs involved in preparing Agarbatti or incense sticks

The costs depend upon the size of the unit which you are going to set up, these include the following

- Costs for machinery and equipment is Rs. 2,00,000

- The costs involved for installation is Rs. 10,000

- The costs involved for rolled sticks is Rs. 15,000

- The costs involved for raw materials is Rs. 20,000

- Costs for other miscellaneous things is Rs. 5,000

Training for Agarbatti making in India

For making these Agarbatti or incense sticks there are many training centers where you can search online to get detailed information as they teach you the formula and explain the methods in making masala Agarbatti by hand rolling on bamboo sticks by using natural things like dhoop, herbal powders, other natural herb powders, Chandan, camphor, etc. Not only incense sticks for religious rituals but also for insect repellents such as herbal mosquito repellent Agarbatti can be prepared by hand roll. There will be no side effects as they will explain and will demonstrate to you the mixing of few raw materials, compositions, proportions, and making the dough by mixing water and the hand-roll on plain bamboo sticks or other sticks to get all varieties of Agarbatti.

Some questions and answers about Agarbatti making a business plan

Some of the frequently asked questions are of the following –

What is the cost of Agarbatti making machine?

The cost of the Agarbatti machine ranges from Rs. 65,000 to Rs. 2,90,000 based on the number of strokes per min.

What is the raw material for Agarbatti?

The raw materials used for preparing Agarbatti are charcoal powder, sawdust powder, jigged powder, and bamboo sticks.

How many Agarbatti companies are there in India?

There are more than 50,000 Agarbatti companies in India that provide employment for women nearly 2 lakhs in number.

How can I sell my Agarbatti in the market?

If you are new to the market, you can sell your Agarbatti at the local level. You can also find the areas like commercial or residential near you where temples and religious places are located more in number.

That’s all folks about Agarbatti Making Business Plan.

In case if you are interested in this: How To Grow Strawberries in Greenhouse.

- Tech Repair Services: Meeting the Demand for Gadget Maintenance

- Maximizing Rewards: Smart Credit Card Habits for Cashback and Points

- Ultimate Guide to Making Money from Goat Milk Business

- How to Start an Agricultural Value Added Product Business

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

- How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

- 10 Value-added Business Ideas for Millets: Low-investment and Highly Profitable

- Why Cleaning Service Business Becoming More Profitable in Metro Cities in India

- 10 Best Businesses to Start in Ayodhya for Profits

- Top Drone Business Ideas in India: Unlocking Aerial Innovation & Opportunities

- Top 10 Service Businesses You Can Start with No Money

- Ultimate Guide to Starting a Home-Based Advertising Agency Business

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

- Construction Company Name Ideas: Guide to Create New Construction Company Names

- 8 Best Small Businesses to Start in Hyderabad: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Massachusetts: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Maryland: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Delaware: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Connecticut: Low-Investment and Profitable

- Top 10 Best Online Pet Business Ideas: Exploring Cats to Dogs

- 10 Best Small Businesses to Start in Colorado: Low-Investment and Profitable

i am interested to know about dhoop batti project

Very nice informations about Agarbatti manufactured buisness.thanks.