How to make money from rice mill business in India

Rice mill plant provides food for approximately 65% population of India, rice is an essential crop in India and it stands as the 45% of total grains production, every Indian have rice in the everyday meal. The raw form of rice is known as paddy, which is not consumed by people directly; it must be processed to achieve rice from paddy.

Ideas to start and make money from rice mill business

Rice mill plant aids to get the rice grain from paddy it eliminates the rice husk and rice bran if you are dwelling in paddy producing area you can begin the rice mill plant, rice mill plant is a money-making business with low capital.

You might also think of how to start a rice mill business, and is rice mill a profitable business, don’t worry we will guide you by providing rice mill business plan, investment, license and registrations required, subsidies available, etc.

Market potential of rice mill plant business to make huge money

Rice is a highly usable food in India; India is having the major market for the packaged rice segment. The raw material from the rice mill plant is rice bran that is having great need as raw material for the solvent extraction unit. There is a great demand for the future of rice mill business in India.

Rice business in India is the leading business in the country especially in rice production, rice milling market, and exporting basmati rice is the class of the rice which is highly required in foreign countries.

If you are thinking of a profitable business then the rice mill plant is one of the best options for you, here in this blog you will get the particularities relevant for initiating the business plan for the rice mill plant.

License and registrations required for rice mill plant business

To begin the rice mill plant or paddy rice mill, you require licenses and approvals from your state government authority.

Registration of firm: You may begin the rice mill plant business as a small to medium scale unit either a Proprietorship or Partnership Firm. If you are initiating this business as One Person Company, then you should register your firm as a proprietorship. For partnership operation, you have to register as an LLP-Limited Liability Partnership (LLP) with the Registrar of Companies (ROC).

Udyog Aadhaar MSME Registrations: Udyog Aadhaar MSME Registration assists you to avail specific benefits of the government scheme.

Factory license: You must apply for a factory license to initiate rice mill production.

No pollution certificate: You must acquire a certificate from the pollution Control Board for the mill operations and establishment.

Acts 1958: You must apply for the Rice-Milling Industry (Regulation) Act, 1958.

PFA and ESIC registration: If your rice mill plant has staff then you must get PFA and ESIC registration for the workers according to labors law.

IEC registration: For expansions such as to export your rice then it is obligatory to obtain IEC code.

FSSAI License: Rice mill plant is classified in the food sector; hence, you must apply for an FSSAI license (Food Safety and Standard Authority of India).

GST registration: After GST rule it is mandatory to obtain GST number for every business.

In case if you miss this: How to Make Money from Mini Flour Mill Business.

Area required for rice mill plant

The selection of land for rice mill units is the tedious task; the locality should have sufficient space for a production unit, machinery, space for drying the rice, and storage of raw material.

You can initiate the rice mill business in around 1000 sqft area, but make sure that the area is nearby to raw material suppliers, especially for the rice plant where the rice is grown.

While choosing a location to ensure that your place has ample water provision, drainage facility, and power supplies.

List of raw materials needed for rice mill plant

The basic raw material for rice mill plants is paddy (raw form of rice crop), the standard of the rice depends on the rice crop thus you must be aware while picking the raw material. The rice is cultivated by the farmer so it is helpful to obtain the raw material from the farmer at a sensible price which will save your money.

To sustain the production yearlong you must stock the raw material or must be in contact with supplies. You must find the farmer or an individual who can separate husk and padding and to obtain rice which is also known as paddy to rice process.

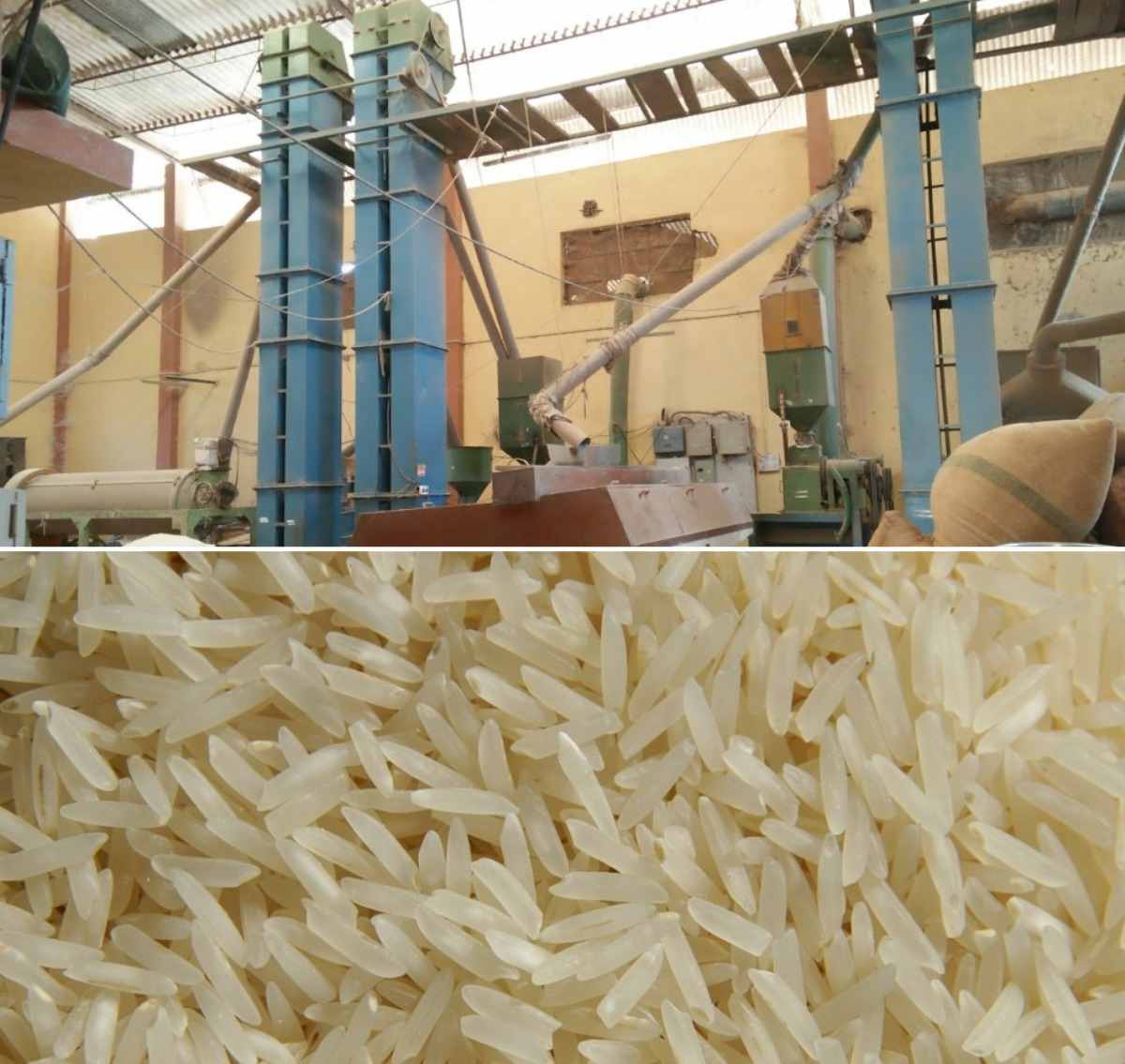

Machinery for rice mill business plant

According to the rice mill processing plant, the type of machinery must be selected from the market; you must be careful to pick the proper machinery needed for your rice mill plant.

The important factor while selecting the machinery is cone slider, production rate, capacity, efficiency, and power equipment. It is also essential to consider whether the machine is meant for a single-stage or multi-stage execution.

List of machinery for rice mill plant:

- Grading machine

- Grain dryer

- Lighting equipment

- Measure and packing machine

- Paddy husker machine

- Paddy separator machine:

- Rice cleaning machine

- Rice color sorter

- Rice de-stoner machine

- Rice milling detection machine

- Rice polishing machine

- Rice whitener machine

After all these you also keep in mind that there should be proper rice mill installation.

How rice mill works

There are three kinds of mill rice processing methods.

One pass method: In this method bran and husk are removed simultaneously.

Two-step process: This is a two-step process, wherein removal of bran and husk is done separately. In this method, the traditional rice mill machine is used which many communities employ. This rice milled for the nearby people locally.

Commercial milling: In this method, several modern machines are employed for the milling process.

Every step in commercial milling is carried out to achieve the finest result because rice here is milled for a broader market.

Steps involved in the rice milling process

Pre-cleaning: The primary step in the rice mill unit is to remove the impurities such as dust, stone, and dirt along with any unfilled rice grain from paddy.

Husking: Husking is the step where the husk is removed and separated from the paddy.

Paddy removals: Paddy separation is known as the separation of husk paddy from brown rice.

Parboiling: Gelatinization of starch inside the rice to enhance the nutritious value of milled rice; it also aids to develop the milling recovery percent during polishing/whitening.

Polishing or whitening: To enhance appearance, rice polishing/whitening is done to the exterior kernel.

Grading and separation of white rice: Separation of rice as per small, large, and broken from head rice.

Blending/Mixing: Mixing of head rice along with a predetermined amount of broken rice.

Weighing of rice: Once the rice is sent through all the processes it will be weighed by using an industrial weighing machine and packed with the various specified amount of baggage.

Bagging/packaging of rice: Preparing the milled rice for transport to the clients for selling, the packaging is essential to make the customer aware of the fact that your product is in the marketplace.

Rice mill business investment or the cost to start a rice mill

You should not miss this: How to Make Money from Egg Hatchery Business.

To start your rice mill business you need to invest a minimum of Rs. 8 to 12 lakhs.

Rice mill machinery cost ranges:

- For 10-20 ton/day minimum price is Rs. 75000/Piece and maximum it goes up to Rs. 200000/Piece.

- For 120-150 ton/day the minimum price is Rs 75000/Piece and maximum it goes up to Rs 75000/Piece

- For 80-120 ton/day the minimum price is Rs 145000/Piece and maximum it goes up to Rs 145000/Piece

The other costs include land, labour, current, and other miscellaneous charges. You can also avail of loans from the banks. You can also avail of subsidies for rice mill project in India. For more details regarding the subsidies for rice mill projects you can go through the NABARD rice mill project.

Subsidies available for rice mill business

The subsidies available for rice mill business in India are 25% which is for the amount below Rs.50 lakhs and 33.33% for the amount above Rs. 50 to 75 lakhs. This can be availed based on the eligibility of the person who applied for the subsidy.

List of banks providing loans for rice mill business in India

Below is the list of the banks which provide loans for rice mill plant business establishment. These are listed here: State Bank of India-SBI, Canara Bank, Punjab National Bank-PNB, Andhra Bank, Central Bank of India, Bank of Baroda, State Bank of Bikaner & Jaipur, UCO Bank, Bank of India, SIDBI, and North Eastern Development Finance Corporation-NEDFi. To reduce the input costs, you can go for commercial rice farming for maximum profits.

Please send this information and many more to my e-mail.

It is very useful to me.

Regards,

Darius

I am very interested in rice processing business. Update me

I am interested for rice mill mini plant plz contact

Pls send me details of rice mill project on my email id

Hi ,

Kindly updates me bcz i am also planning to incorporate mini rice mill kindly mail for Budget of mini rice Mill Thanks

Guidance needed to start mini ricemill with dehusking of millets and pulses in my village Elenjemboor under PMEGP scheme using partly in solar power.

.

Please send me your guidance and support for starting this unit in Ramnad dt in Tamil Nadu.

I want to set up in 8 to 10 lakhs, please contact me.

Plz contact I’m interested and planning to rice business

Interesting

Sir I want to start new rice mill plant so please help me sir and how to start and how get licence sir please…..?

Want to start rice packing industry. Please advise