How to Air Bubble Sheet Making Business

Introduction

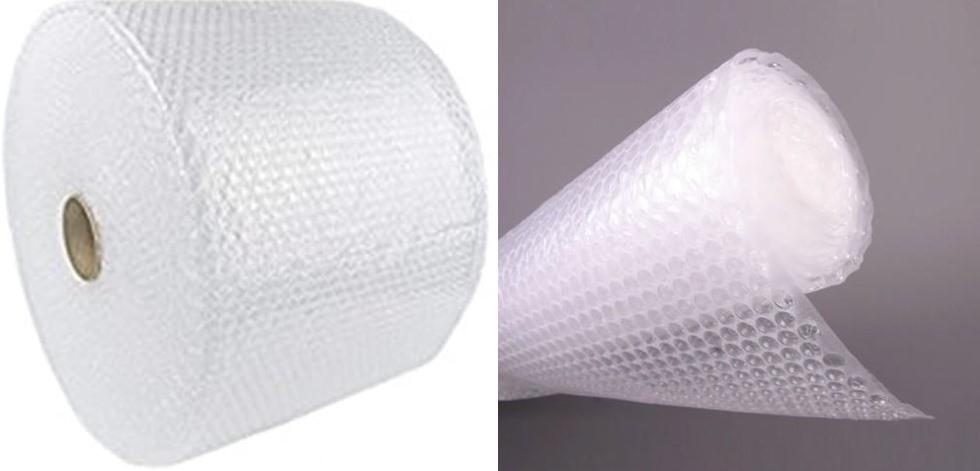

Air bubble sheet making with other associated products is a profitable business in the packaging segment. Besides the sheet, you could plan to make air bubble bags, air bubble films, air bubble rolls, etc., based on your client’s demand. Air Bubble Wrap Sheets, are flexible and transparent plastic sheeting with several small air pockets. The sheets act as a cushion and scratch-proof material. They are used to pack the items while shipping and storage.

Air bubble film is a two-layered laminated low-density polyethylene film having air trapped in it, between the two layers in bubble form in some orderly manner. The bubbles could be of different sizes. The size of the bubble and thickness of the film is determined based on the type and weight of the material to be packed.

A step-by-step guide to Air Bubble Sheet Making business

Why Air Bubble Sheet has great demand in the market?

Air bubble sheets are proven and efficient wrapping material used for packing electronics, glassware, electrical, machinery, automobile spare parts, and in several industries. The air bubble sheet line material is soft in touch and the bubble-like protruding features save the products from any type of damage or scratches during shipping processes. Air bubble sheet unit is an affordable venture for producing safe stuffing products for brittle as well as heavy goods. Air bubble sheet machines can generate sheets of various sizes and lengths.

Some of the very effectiveness and advantages of air bubble sheet are:

- Excellent water resistance

- Atmospheric resistance

- High dielectric properties

- Resistance to pests and white ant

- Easy and economical packaging method

- Very high shock absorption characteristics

- Resistant to most acid and alkalis for a sensible duration.

- Light to carry, attractive look, washable, printable, and heat sealable.

- Majorly it will be employed in the below sections.

- For packaging of fragile goods likes crockery etc.

- Packing electronics and electricals goods.

- For Plastic machinery parts packaging.

- Precious antique packaging.

- Pharma sector for Pharmaceutical bottles, chemical packaging, vials packaging, etc.

- Glassware, handicraft items, and ceramic products, packaging.

- Scientific instrument packaging

- Engineering and automobile spare parts packaging.

Market potential of Air Bubble Sheet making business

The growing demand for electronic products in current years has led to the increased packaging need using air bubble film which has channelized to be a good scope for new entrepreneurs towards a profitable venture. Besides packaging usage, air bubble film is extensively employed in developed countries for swimming pool cover.

The packaging industry in India has a projected turnover of Rs. 11,500 crores, which is mounting at the rate of 18 percent every year. The changing pattern of the Indian Consumer behavior mostly affects the packaging segment as the direct expenditure incurred by establishments to make the products attractively packaged is growing every day. The industry has a huge perspective and it is emergent at a fast pace.

License, permissions and registration required for Air Bubble Sheet making business in India

For initiating an air bubble sheet-making business in India, you must obtain the registration for your company first with ROC. Avail trade License. Get the mandatory GST registration. Air bubble sheet making does not cause any pollution so ‘No Objection Certificate’ from state PCB-Pollution Control Board. It is also important to protect your brand name by registering a Trademark.

Business Entity: The first registration for any business is to register it as a business entity by knowing about the form of the organization. It could be as a sole proprietorship or a partnership or a limited liability partnership or a one-person company. This will help in availing a few benefits to the business and must, therefore, be selected carefully before registering the business at the Registrar’s office.

Shop Act or Trade License: The Air Bubble sheet Making business for example in Maharashtra, India requires applying for a Shop Act License from the local municipal authority to run the business. This license helps manage the working conditions along with working hours, leaves, wages, holidays, etc. of the employees and supports the business to run smoothly.

Udyog Aadhaar Registration: An Air Bubble Sheet Making business is categorized as a small business and hence it must be registered under Udyog Aadhaar which is a registration and recognition for MSMEs- micro, small, and medium enterprises.

GST Registration: Every business, including the Air Bubble Sheet Making business, should associate with taxes at some point and for monitoring a single uniform taxation structure, the business should get a common GST number which stands for Goods and Service Tax.

BIS certification: Apart from these registrations the business should get BIS certification as well as tax liabilities.

Business plan for starting Air Bubble Sheet Making Business

Before initiating any business especially small-scale manufacturing it is significant to have a business plan. It is always suggested to prepare a customized project plan according to your savings/ capital and required production capacity. The business plan, including the marketing policies, business objective, and mission declaration.

A proper marketing plan is completely important in this business. Also, financial planning relies on that. You must have a proper idea about the selling procedure. You can try for a distribution network. However, it demands much of your capital to sustain the circle and enhancing business.

The machinery required for starting Air Bubble Sheet making business

When beginning a bubble sheet-making business, you must install Polycell Bubble Sheet Making Machine. With this automatic machine, you can get air bubble sheets.

Besides this, you can also get an air bubble film extrusion line, air bubble film foil lamination machine, air bubble film laminated line, air bubble film lamination line, air bubble film extrusion machine, air bubble film making line, air bubble film package machine, etc. These are PE air bubble film extrusion lines.

Raw materials required for starting Air Bubble Sheet making business

You might obtain LDPE granules as raw materials. In the manufacturing unit, you should avail of 373 KW. Power supply on average. Another utility item you should get is a facility of water availability. This is for cooling purposes.

Process of making Air Bubble Sheet

LDPE granules fed into the hoppers of 100 mm and 75mm extruder respectively are sent through the extruders, where they will be melted, plasticized, and introduced through the two-layer nips of T-die. In the die, two layers of LDPE sheets of necessary thickness are formed together.

These layers are passes through cooling rollers which are made of synthetic silicon, here the air bubbles are formed over the roller and next laminated by forcing one above the other layer by giving high pressures. At this stage, an air bubble is formed due to a vacuum over the outer surface as it is cooled and along with the second layer together and the lamination is done simultaneously. Then the layers are cooled to sent the trimmed forward and then they are taken through take-off rollers and then lastly to the winder.

You can also prepare bubbles into two-layer bubble film, 3 layers bubble film, 5 layers bubble film, and other multilayer bubble films. Air bubble sheet making can be done in different colors as well.

In case if you need this: Goat Farming Plan.

The investment required for starting an Air Bubble Sheet making business

Cost of the Air Bubble Sheet making machine (automatic) – Rs. 1,75,000

Cost of raw materials – Rs. 75,000

Cost of machinery and other requirements – Rs. 1,50,000

Packaging cost – Rs. 25,000

Other expenses – Rs. 25,000.

The total expenses required to start an Air Bubble Sheet manufacturing business is Rs. 3,50,000

Profit in Air Bubble Sheet Making business

Because of the high demand, the profit margin in the Air Bubble Sheet Making business is high. One can gain more than 3,000 – 4,000 rupees every day. The profit margin in the Air Bubble Sheet-making business is much more for wholesale dealers. If you carefully follow the above-mentioned steps you can earn income through Air Bubble Sheet making business though you have spent less capital.

In case if you are interested in this: How To Start Seed Processing Business In India.

Where to sell the Air Bubble sheet

You can sell your Air Bubble Sheet in local markets or you can even sell in the wholesale stores. You can also register in B2B websites and B2C websites in online markets to promote your product.

You can also sell your products in supermarkets, small stores in shopping malls, etc. Advertise your product through social media to get a huge number of clients in this way you can increase and promote your business. Even though there are several Air Bubble Sheet manufacturers in India, but the demand for encouraging the new product is also high because of its uses. So, you need not worry about the market. You can sell your product based on the Air Bubble Sheet wholesale price in India.

Marketing strategies to promote Air Bubble Sheet Making Business

As Air Bubble Sheet are consumer goods you must be careful on creating brand equity, maximize brand perceptibility, and endorsing brand usage. You can begin selling them locally by starting a distribution channel. Approach some retail brands to have a deal with your business. In India hotels, clubs, restaurants, business houses, hospitality management companies are the major customers of Air Bubble sheet.

You can plan for some bulk manufacturing for the Air Bubble sheet. Register your product with diverse online shopping platforms to entice online consumers. Get prepared to establish an online presence in your Air Bubble Sheet-making business. Give some clear informative facts there about numerous varieties of packaging materials.

- Handicraft Making at Home: A Small Profitable Business Idea

- Pet-Tech Startups: Innovations for Animal Lovers

- Tech Repair Services: Meeting the Demand for Gadget Maintenance

- Maximizing Rewards: Smart Credit Card Habits for Cashback and Points

- Ultimate Guide to Making Money from Goat Milk Business

- How to Start an Agricultural Value Added Product Business

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

- How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

- 10 Value-added Business Ideas for Millets: Low-investment and Highly Profitable

- Why Cleaning Service Business Becoming More Profitable in Metro Cities in India

- 10 Best Businesses to Start in Ayodhya for Profits

- Top Drone Business Ideas in India: Unlocking Aerial Innovation & Opportunities

- Top 10 Service Businesses You Can Start with No Money

- Ultimate Guide to Starting a Home-Based Advertising Agency Business

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

- Construction Company Name Ideas: Guide to Create New Construction Company Names

- 8 Best Small Businesses to Start in Hyderabad: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Massachusetts: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Maryland: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Delaware: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Connecticut: Low-Investment and Profitable

Interested doing this business let me know the details

Hi,

I would like to know more details about this to start this business at my locality. Please help me on this.