Many people think that bamboo straws are just another green fad, but the truth is that they offer a sustainable way to consume your favorite beverages. If you’re considering starting a bamboo straw business, there are a few things you need to know about the manufacturing process, investment, profit, and machine cost. This article will explore all these topics so you can make an informed decision about starting your own business.

Bamboo straw business plan

Bamboo straw manufacturing business plan

A bamboo straw manufacturing business plan should include a detailed description of the manufacturing process, expected investment and profit, and the cost of the machine required to produce the straws. The bamboo straw manufacturing process is relatively simple and can be done with just a few pieces of equipment. First, the bamboo is cut into pieces that are the right size for the straws. Next, a machine is used to hollow out the inside of the bamboo pieces so they can be used as straws.

In case you missed it: How to Start Recycling Business in California: Business Plan, Investment, Profit, License, and Requirements

Finally, the bamboo straws are cut to length and polished to give them a smooth finish. The expected investment for a bamboo straw manufacturing business is relatively low. The biggest expense will be for the machine to hollow out the inside of the bamboo pieces. This machine will cost around $2000. Other expenses include the cost of raw materials and packaging. The total expected investment for a small bamboo straw manufacturing business is between $3000 and $4000.

The profit potential for a bamboo straw manufacturing business is good. Each straw costs only a few cents, so there is much room for markup. It is estimated that a small bamboo straw manufacturing business can generate annual sales of between $30,000 and $50,000. The machine required to produce bamboo straws costs around $2000. This machine will be able to produce enough straws for a small business to generate annual sales of between $30,000 and $50,000.

How to start a bamboo straw manufacturing business

Bamboo straws are eco-friendly alternatives to plastic and paper straws, becoming very popular in recent years. Starting a bamboo straw manufacturing business can be a great way to tap into this growing market. This blog post will outline the process of starting a bamboo straw manufacturing business, including the investment required, the profit potential, and the cost of machines.

Starting a bamboo straw manufacturing business requires a significant investment in machinery and equipment. The cost of machines can range from $10,000 to $50,000, depending on the size and capacity of the operation. However, the total investment required will be much higher when you factor in raw materials, packaging, and shipping costs. The profit potential for a bamboo straw manufacturing business is good.

In case you missed it: How to Start Restaurant Business in California: Business Plan, Requirements, Investment, and Profit

Bamboo straws sell for an average price of $0.25 each, so that a successful operation could generate hundreds or even thousands of dollars in monthly sales. When starting a bamboo straw manufacturing business, there are several things to remember. First, you need to find a reliable source of raw materials. Bamboo is not typically grown in North America, so you will likely need to import it from Asia or Africa. Second, you need to invest in high-quality machines that can produce large quantities of bamboo straws quickly and efficiently.

Material required to start bamboo straw making

- Bamboo poles of various diameters

- A sharp knife or saw

- A drill

- A hand drill or power drill

- PVC pipe or bamboo tube (for the mold)

- Sandpaper

- Rope or string

- A pot of boiling water

- A stove

- A bowl of cold water

The bamboo straw manufacturing process

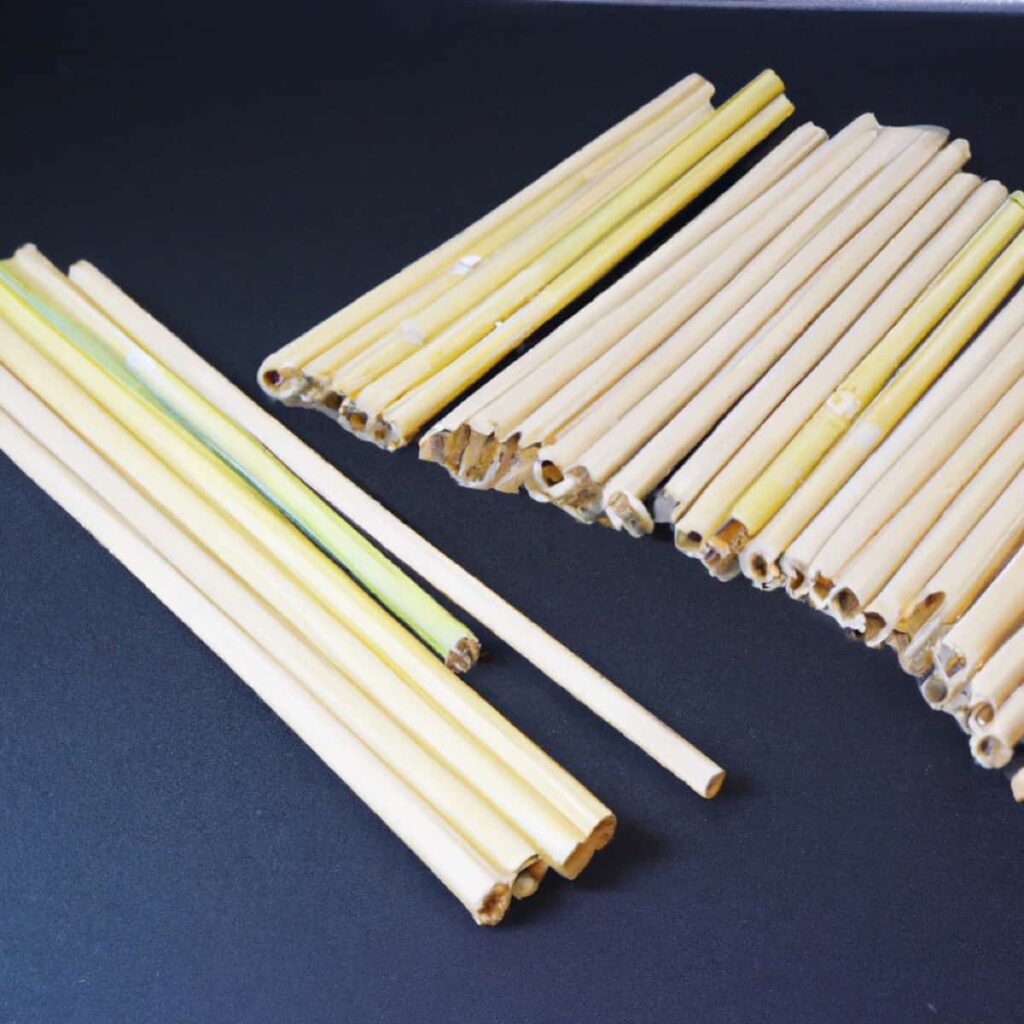

Bamboo straws are made from the hollow stem of the bamboo plant. The stem is cut into pieces and then split lengthwise. The split pieces are then sanded smooth and cut to size. The manufacturing process of bamboo straws is simple and does not require special equipment. You need only a sharp knife and good sandpaper. The first step is to cut the bamboo stem into pieces. The pieces should be about 3-4 inches long.

In case you missed it: How to Start Laundry Service Business in California: Business Plan, Investment, Profit, and Requirements

Next, use a sharp knife to split the bamboo pieces lengthwise. You can do this by cutting along the grain of the bamboo. Once the bamboo is split, use sandpaper to smooth out the rough edges. Be sure to sand evenly, so the final product has a nice finish. Finally, cut the bamboo straws to the desired size. Bamboo straws can be any length you want, but they are typically about 8-10 inches long.

Investment required for starting a Bamboo straw manufacturing business

The investment required to start a bamboo straw manufacturing business is not very high. The main cost will be for the machines needed to make the straws, which can range from $2,000 to $10,000 depending on the type and size of the machine. Other costs include raw materials, packaging, and shipping. The total investment required to start a small bamboo straw manufacturing business could be as low as $5,000.

You will need to purchase a few key types of equipment to start. These include a cutting machine, a drying oven, and a straw-making machine. The cost of these machines will vary depending on the size and capacity of the machines. For example, a small cutting machine may cost $2,000, while a large one may cost $10,000. In addition to the cost of the machines, you will also need to factor in the cost of raw materials. Bamboo is inexpensive, but you will also need to purchase other materials, such as glue and packaging.

The total cost of raw materials will depend on how much bamboo you need and the price of other materials. Finally, you will need to factor in shipping costs to sell your bamboo straws online or through retailers. Shipping costs will vary depending on the weight and size of your products. For example, shipping a small package of bamboo straws within the US may cost around $5, while shipping internationally may cost around $20.

In case you missed it: Earning 30 Lakh Rupees from the Pearl Farming Business: A Success Story of Pearl Farmer in India

Profit in Bamboo straw manufacturing business

There are numerous benefits to setting up a bamboo straw manufacturing business. Not only is bamboo a sustainable and eco-friendly material, but it’s also strong, making it an ideal choice for straws. And because bamboo straws can be reused multiple times, they offer a more sustainable alternative to plastic straws. Manufacturing bamboo straws is relatively simple and does not require any specialist equipment.

Bamboo can be cut into thin strips using a sharp knife or mandoline slicer, which can then be shaped into straws using a mold or template. Once the desired shape has been achieved, the straws can be sanded down to create a smooth finish. The investment required to set up a bamboo straw manufacturing business is relatively low. The main costs will be purchasing the raw materials and necessary equipment.

However, the startup costs are relatively low because there is no need for expensive machinery or specialist knowledge. The profit potential of a bamboo straw manufacturing business is significant. With the right marketing strategy, it’s possible to generate high sales and achieve healthy profits. There are several ways to market bamboo straws, including online channels such as social media and e-commerce platforms, as well as offline.

Bamboo straw manufacturing machine cost

The cost of bamboo straw manufacturing machines varies depending on the type and size of the machine you purchase. For example, a small hand-operated machine may cost as little as $100, while a large industrial machine could cost tens of thousands of dollars. The type of machine you need will depend on the scale of your business. For example, a small hand-operated machine may be all you need if you only make a few hundred bamboo straws daily. However, an industrial machine will be necessary if you plan to produce millions of straws daily.

In case you missed it: Top 10 Profitable Small Business Ideas in California: Low Investment and High Profits

The cost of raw materials also needs to be considered when calculating the cost of your bamboo straw manufacturing operation. Bamboo is relatively cheap, but the cost of shipping and handling can add up if you’re not careful. Finally, don’t forget to factor in the cost of labor when calculating the overall cost of your bamboo straw manufacturing business. While it’s possible to operate a small business with just a few employees, you’ll need to hire more workers if you want to ramp up production.

The target market for bamboo straws

More people have become aware of the detrimental effects of plastic straws on the environment, and there is an increasing demand for eco-friendly alternatives. Bamboo straws are a great option for those looking for a sustainable and reusable product. Many businesses can cater to this growing market, from small startups to large corporations. However, it is important to consider your target market when starting a bamboo straw business.

Who will you be selling your straws to? The most obvious target market for bamboo straws is individuals looking to reduce their use of plastic straws. This includes environmentally conscious people who have switched to using reusable products to be more sustainable. However, there is also a growing market for bamboo straws among businesses such as restaurants, cafes, and bars.

Many establishments are now looking for ways to reduce their environmental impact, and switching from plastic straws to bamboo straws is one way to do this. Therefore, when considering your target market for bamboo straws, it is important to consider both individuals and businesses who may be interested in your product. With a clear target market in mind, you can create a marketing strategy to help you reach your potential customers and grow your business.

Is bamboo straw eco-friendly?

The global market for bamboo straws is expected to reach $13.5 million by 2024, up from $7.3 million in 2019, according to a report by Transparency Market Research. The demand for eco-friendly and sustainable products has increased in recent years as consumers become more alert to the environmental impact of their purchases. Bamboo is a sustainable material used to create various products, including straws.

In case you missed it: Candle Making Business Plan: How to Start, Requirements, Manufacturing Process, Cost, and Profit

Bamboo straws are a substitute for plastic straws, which are a major source of pollution. Bamboo straws are durable and reusable, making them a more sustainable option. There are a few different ways to manufacture bamboo straws. The most common method is to cut the bamboo into pieces and then hollow out the center of each piece with a drill bit. This method produces long, thin straws that can be used for drinking beverages or stirring coffee or tea.

Another manufacturing method involves cutting the bamboo into small pieces and grinding them into a powder. This powder can create biodegradable plastic formed into straws using molding techniques. The investment required to start a bamboo straw manufacturing business varies depending on the size and scope of the operation. For a small operation, the investment may be as low as $10,000. The investment could be up to $1 million for a larger operation. The cost of machines used to manufacture bamboo straws ranges from

How long do bamboo straws last?

Assuming proper care, bamboo straws can last a very long time. Some people have had bamboo straws for over two years without any issues. Of course, there will be some wear and tear like anything else. The best way is to wash them after each use and let them air dry completely. It’s also important to avoid using harsh cleaning chemicals or abrasive scrubbing pads, as these can damage the surface of the straws. With proper care, your bamboo straws should be able to give you many years of service.

Conclusion

Starting a bamboo straw business can be lucrative for entering the eco-friendly market. With the right manufacturing process and investment, you can create a product that is not only sustainable but also profitable. We hope this article has given you some insights on how to get started and what to expect in terms of cost and profit.

- Handicraft Making at Home: A Small Profitable Business Idea

- Pet-Tech Startups: Innovations for Animal Lovers

- Tech Repair Services: Meeting the Demand for Gadget Maintenance

- Maximizing Rewards: Smart Credit Card Habits for Cashback and Points

- Ultimate Guide to Making Money from Goat Milk Business

- How to Start an Agricultural Value Added Product Business

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

- How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

- 10 Value-added Business Ideas for Millets: Low-investment and Highly Profitable

- Why Cleaning Service Business Becoming More Profitable in Metro Cities in India

- 10 Best Businesses to Start in Ayodhya for Profits

- Top Drone Business Ideas in India: Unlocking Aerial Innovation & Opportunities

- Top 10 Service Businesses You Can Start with No Money

- Ultimate Guide to Starting a Home-Based Advertising Agency Business

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

- Construction Company Name Ideas: Guide to Create New Construction Company Names

- 8 Best Small Businesses to Start in Hyderabad: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Massachusetts: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Maryland: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Delaware: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Connecticut: Low-Investment and Profitable

- Top 10 Best Online Pet Business Ideas: Exploring Cats to Dogs

- 10 Best Small Businesses to Start in Colorado: Low-Investment and Profitable

- Top 10 Profitable Small Business Ideas in California: Low-Investment Tips

- From Little Rock to Fayetteville: Top 10 Profitable Small Business Ideas in Arkansas

- Top 10 Profitable Small Business Ideas in Alabama: Discover Opportunities in Alabama’s Growing Cities

- Top 10 Profitable Small Business Ideas in Arizona: Discover Opportunities in Arizona’s Growing Cities

- Golf Business Ideas: Exploring Golf Course Money Making Ideas

- Low Capital Profitable Small Farm Ideas: Farming Ideas to Make Money

- How to Write a Business Plan for Daycare: Exploring from Financial Projections to Risk Management

- Home Daycare License Requirements: Exploring State-wise In-home Daycare Requirements

- How Profitable is Day Care Business: How Much Does a Daycare Owner Make a Month or Year?

- How to Open a Daycare Center in Toronto, Canada: Business Plan, Licenses and Permits

- How to Start Meal Prep and Delivery Services: A Popular Business Idea

- How to Start a Milk Chilling Plant Business

- How to Start Coconut Shell Charcoal Business: Business Plan for Maximizing Profits