Eraser Manufacturing Project Report, Business Plan

Introduction

When you are planning to invest in any business you must have comprehensive knowledge about the business strategy, awareness about the required raw materials, essential machinery, and the process of manufacturing the product.

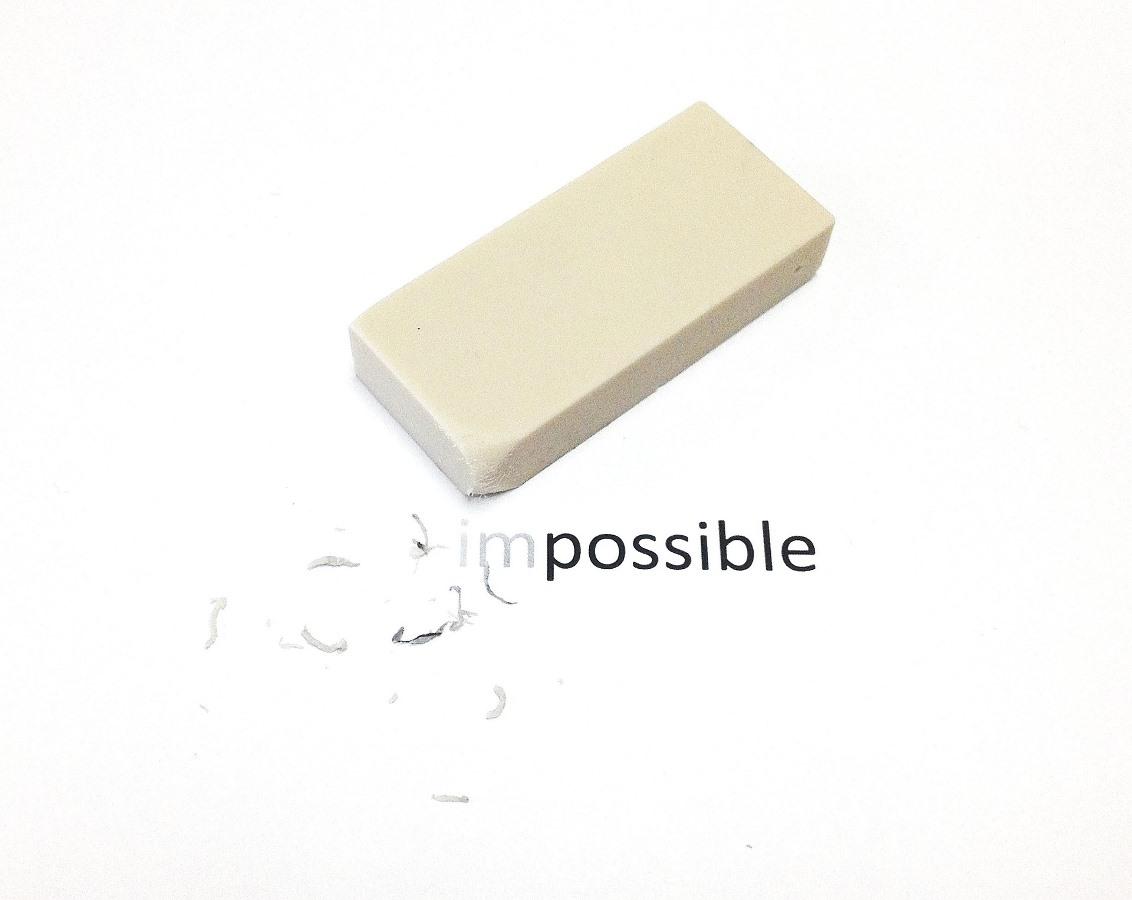

In this article, we will highlight the essential aspect involved in starting rubber eraser manufacturing. A rubber eraser is a very essential tool for students. The eraser meant to delete the errors. Usually, an eraser helps to erase while writing with a pencil. Erasers have a rubbery feel and are mostly seen as white or pink, but they can be produced in various colors as per the need or demand. In addition, the eraser is used by typewriters, bookkeepers, tailors, etc. It is even one of the vital elements in school stationery.

The eraser manufacturing is easy and simple. The eraser is obtained using natural rubber and the investment need is also moderate for a small-scale unit. Thus, it could be a perfect option to consider this rubber eraser manufacturing company, when you plan for a start-up with less capital.

Eraser Manufacturing Project Report and Business Plan in India

Market potential of Eraser Manufacturing Business

Currently, there is a high requirement for erasers in the market. Even we can see that there is an increasing demand for a worthy eraser that can be perfectly useful for erasing purposes. Particularly some special pencils end with erasers, certain wooden pencils at their endpoints come with rubber. The market for high-quality erasers tends to grow education sector is developing.

Business plan to set-up Eraser Manufacturing Unit

It is relatively easy than other businesses to begin an eraser manufacturing business. As the method of manufacturing is fast it is very convenient to handle the unit with less staff. However, you must craft a proper business plan before initiating this business.

You need to particularly mention the specific type of rubber you plan to manufacture. Apart from that, the packaging process and marketing ideas need to be explained. Often, the business plan must include the analysis of the financial aspects of the business. Therefore, you should be ready with the fixed expenses, know about your target market, and explain your expected revenue, product and repair options, expansion ideas, etc. This will even attract investors and even banks will consider providing bank loans.

License, permissions, and registration required for Eraser Making Business in India

It is essential to have your company registered even if it’s a small-scale unit business. For small-scale businesses, you can plan the company as a proprietorship. However, you need to identify and determine the form of business organization based on the investment model.

The eraser-making business does not have particular licenses but you must refer to your state laws and even contact the local municipality for any such approvals before starting. Though the GST registration is mandatory for manufacturing business and applies for the online Udyog registration for MSME.

- Business Entity

- Shop Act or Trade License

- Udyog Aadhaar Registration

- GST Registration

- BIS certification

- No Objection Certificate

- Business Pan Card

- Current Bank Account

Setting up the Manufacturing Unit of Eraser Making Business

For a small-scale rubber eraser manufacturing around 1000 sq. ft covered area along with water and power connection is mandatory. It is essential to check that transportation is also available from unit to market and to nearby suppliers for procuring raw materials easily.

The area should be allocated properly for installing the machinery, raw, material storage, and for storing the end products. You must keep some are for tasks associated with administrative work.

Area required for Eraser Making business

To establish any kind of business you need to acquire 1000-1500 sq. ft. of land. It is based on scalability of your business and if you want to do then it is based on the activities of your business. If you are arranging this business through machinery then you will not need a larger area.

Machinery required to start Easer Making Business

The major portion of fixed capital is spent on the purchase of the eraser-making machine. The cost of the machinery is determined based on efficiency and the production output. Acquire the equipment from a trustworthy company. Make sure you get the warranty of the machinery and also enquire if they provide any assistance while installation in your unit.

Eraser Manufacturing Machine Unit

An automatic eraser making machine is employed for the manufacturing of an eraser and this is easily obtainable.

Eraser making machine price – It is based on which type of machine you are buying, i.e. if you purchase eraser making machine with high manufacturing ability. Then it will be charged that ranges from Rs. 3 lakhs to Rs. 10 lakhs and whereas the one with lower capacity will be less expensive.

Few essential types of machinery needed for the unit are mentioned below

- Hydraulic press

- Cutter and grinder

- Boiler

- Stamping machine

- Rubber mixing roll mill

Commonly, the machine for eraser making is integrated with various other components. It primarily has the arrangement for kneading and a frequency control inverter. There is also a jacket for heating or cooling, outside the cylinder. For heating, even hot oil, steam or power can be used based on the availability. The frame is made of stainless steel for the high-quality machine.

Raw materials required to start Eraser Making Business in India

Generally, natural rubber is the main raw material for your business. Starch, lithopone, petrolatum, vulcanized waste rubber, abrasive, and sulfur are a few of the components. Moreover, you have to get the materials needed for packing. Usually, a hard paper single sheet is appropriate for sealing. About 12 pieces of rubber are packed in a box and sent for sales to the wholesale market and retailers.

Procedure and process of Eraser Manufacturing – A Step by Step Guide

You can manufacture rubber erasers with different raw materials, for instance, synthetic rubber or even natural rubber, and several other thermoplastics. In this article, we will consider the one made using natural rubber.

In the first step, in a blending double roll mill, you have to grind the natural rubber with other compounds apart from sulfur. Include sulfur and start mixing for some duration. Once you do the first mixing, you will get a layer of the substance of desired thickness.

By steam or with an electric heated hydraulic press, it is sent and vulcanized. In the end, they are cut to the standard size and completed. However, erasers have different compositions based on their type.

Eraser Manufacturing Project Report/Economics of Eraser Manufacturing Business in India

In case if you miss this: How To Start A Tea Bag Making Business In India.

Fixed Capital

a. Land: Rs. 10,80,000

b. Building: Rs. 24,04,800

Total Land and Building: Rs. 1,32,04,800

c. Machinery cost: Rs. 1,00,000

d. Other fixed costs

Furniture: Rs. 60,000

Transportation: Rs. 65,000

Van: Rs. 50,000

Computer: Rs. 40,000

Total Machinery costs: Rs. 2,15,000

Total fixed assets: a + b + c + d = Rs. 10,80,00 + Rs. 24,04,800 + Rs. 1,00,000 + Rs. 2,15,000 = Rs. 1,35,19,800.

Working Capital

Raw materials cost per year

Rubber: Rs. 9,00,000

Facits: Rs. 1,20,000

Sulfur: Rs. 72,000

Quartz powder: Rs. 1,20,000

Total raw material: Rs. 12,12,000

Wages and Salaries: Rs. 5,88,000

Utilities: Rs. 72,000

Administrative expenses: Rs. 1,17,600

Total working capital: Rs. 19,89,000

Total project fund: Rs. 1,50,00,000.

Sources of fund

Owned capital @ 40%: Rs. 60,00,000

Borrowed capital @ 60%: Rs. 1,50,00,000

Interest rate on capital: Rs. 12,60,000

Depreciation: Rs. 2,74,230

Total cost of production: Rs. 35,23,830.

Profitability Analysis in Eraser Manufacturing Business in India

Gross profit per year: Rs. 26,22,000

GP ratio: 65.55%

Net Profit Ratio = Net Profit/sales x 100 = 6,27,353/40,00,000 x 100 = 15.68%.

Break Even Point

BEP = Fixed Cost / Contribution x Utilize Capacity = 18,28,230/23,04,400 x 50% = 39.67.

- Handicraft Making at Home: A Small Profitable Business Idea

- Pet-Tech Startups: Innovations for Animal Lovers

- Tech Repair Services: Meeting the Demand for Gadget Maintenance

- Maximizing Rewards: Smart Credit Card Habits for Cashback and Points

- Ultimate Guide to Making Money from Goat Milk Business

- How to Start an Agricultural Value Added Product Business

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

- How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

- 10 Value-added Business Ideas for Millets: Low-investment and Highly Profitable

- Why Cleaning Service Business Becoming More Profitable in Metro Cities in India

- 10 Best Businesses to Start in Ayodhya for Profits

- Top Drone Business Ideas in India: Unlocking Aerial Innovation & Opportunities

- Top 10 Service Businesses You Can Start with No Money

- Ultimate Guide to Starting a Home-Based Advertising Agency Business

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

- Construction Company Name Ideas: Guide to Create New Construction Company Names

- 8 Best Small Businesses to Start in Hyderabad: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Massachusetts: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Maryland: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Delaware: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Connecticut: Low-Investment and Profitable