Introduction to make money from cement brick manufacturing Business

Hello everyone! Today let us discuss the business idea which is a vital thing in the construction field. We all know how the construction of buildings, offices, houses, apartments, etc. is increasing day by day. There are ‘n’ numbers of construction companies in India. Now let us go into the details of the manufacturing business idea, which major requirement in the construction field that is ‘Cement brick making business.

Ideas to start and make money from the cement brick manufacturing business

The cement brick business is running with good profits in recent times. The cement brick manufacturing business provides a good opportunity for many job seekers. There are many questions and doubts among individuals about whether or not this cement brick manufacturing industry could be a good start-up. So, let us get into the details and clarifications of many doubts that generally arise when you think of setting up this industry. This blog provides you all the information about how to start a cement brick manufacturing business and make it a successful one. The most important aspects you need to know are the average cost of starting a cement brick plant or factory in India, the raw materials required for the manufacture, detailed knowledge about the process of manufacturing the cement bricks including the price of cement brick making machine, etc.

The market potential for cement brick manufacturing to make great money

Cement bricks, being the modern construction materials, have an increasing demand due to the growing construction activity throughout the country day by day. In the construction field, nowadays the conventional stones and bricks are being substituted or replaced by cement concrete bricks because of certain advantages offered by these cement bricks. They offer faster construction speed, longer durability, uniform quality, requires lower labor force involvement than conventional stones and bricks. In the present-day scenario, these cement concrete bricks are being used for a wide range of constructions such as commercial buildings, industrial buildings, and residential buildings. There is always a high demand for cement concrete bricks in all the cities and other urban centers as well. When compared to conventional stones and bricks, these cement concrete bricks are lightweight which can be placed easily. Apart from all these, you need to design an excellent cement brick-making business plan to make it a successful one. They can also confer economies in terms of foundation cost and cement consumption. By knowing the above advantages, one can say that this cement bricks manufacturing industry can be a good start-up.

Raw materials required for initiating cement brick making business

In case if you miss this: How to Make Money from Dal Mill Business.

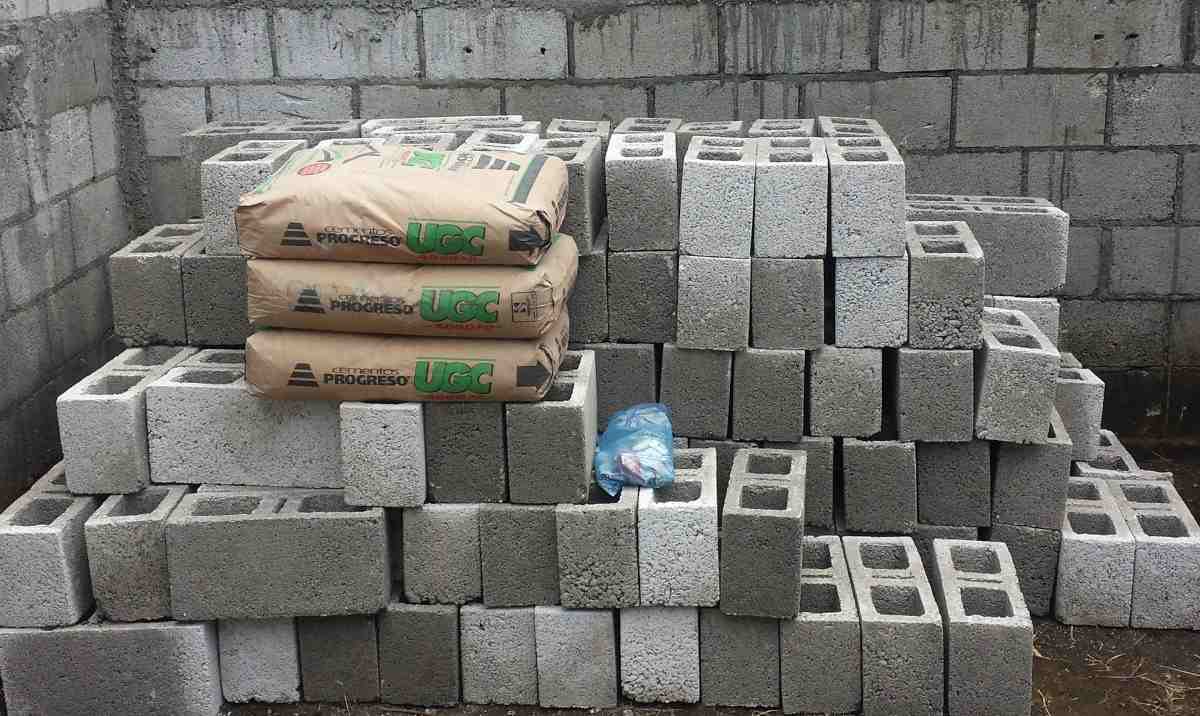

The concrete cement bricks are huge when compared to the usual clay building blocks. The raw materials required for the manufacture of cement bricks are as follows:

- Quality cement is required as it is the main raw material for the business

- The second important thing, small stone chips with 0.5 inches

- Sand

- Stone dust

These above-listed raw materials can be obtained from the nearby districts as well as from the other states of India.

Cement bricks manufacturing process

In the current days, cement bricks have a key role in the modern construction industry as they are cost-effective. The manufacturing process of cement bricks involves the following simple steps. A brief explanation of the above steps is as follows:

Step 1: Proportioning

The first step for making the cement bricks is proportioning. To produce the accurate quality of the cement brick, the concrete and the raw materials should be mixed in a suitable amount determined based on the concrete cement bricks mixture ratio, by following the procedures: mixing, placing, and curing which is called “Proportioning”. As per the Indian Standard Specifications, the combined aggregate content (used for manufacturing cement bricks) in the concrete mix should not be more than 6:1 by volume of Portland cement. In terms of weight basis, this ratio is taken in an average approximation at 1:7.

Step 2: Mixing

The second step in the process of cement brick manufacturing process is ‘mixing’. In this step, the accurate procedure has to be followed to avoid the formation of lumps hence this should be completely spread all over the surface. Hence cement, water, and concrete should be thoroughly mixed.

Step 3: Rotating

The third step in the manufacture of cement bricks involves rotating. In this step, all the raw materials including water are collected in a concrete mixer and the rotation is done for about 1 and a half minutes.

Step 4: Compacting

The fourth step involves compacting. The main purpose of this step is to fill the air pockets with concrete as a whole avoiding free water movement through the concrete. Excessive compaction results in the formation of water layers or water pockets with a bad effect on the quality of cement bricks. Thus, it should be avoided.

Step 5: Curing

Curing is the fifth step in the manufacture of cement bricks. The cement bricks that are removed from the mold are protected until and unless they are hardened enough for proper handling without any damage. The cement bricks are protected from sun and winds for about one 1day or 24 hours. Once the cement bricks are sufficiently hardened, they are cured in a curing yard for a minimum of 21 days to allow complete moisturization of the bricks.

Step 6: Drying

The last step in the manufacturing of cement bricks involves drying. In this step, the concrete bricks shrink slightly with the loss of moisture. Then these bricks should be allowed to dry out slowly either by using drying machines or by normally drying it out in a shade. The cement bricks size should be 9 In. X 3 In. X 2 In.

You should not miss this: How to Make Money from Fish Feed Production.

Investment or the cost to start a cement brick manufacturing business in India

In India, the average cost of starting or opening a cement brick plant or factory depends on the way you establish the plant. There are two different ways of establishing a cement brick plant in India. They are:

- Semi-automatic cement brick manufacturing plant

- Fully automatic cement brick manufacturing plant

A brief explanation of these two types is given as follows:

Semi-automatic cement brick manufacturing process

A semi-automatic cement brick plant or factory involves the use of the following machinery:

- Concrete mixer

- Water dosing pump

- Curing beds

- A hydraulically operated concrete block making machine with quadruple vibrators

- A Platform electronic weighing scale

- Ram

- Molds

The price of a semi-automatic cement brick manufacturing machine ranges from Rs. 1,00,000 to Rs. 2,00,000

Fully-automatic cement brick manufacturing process

By establishing this way of cement brick plant or factory, one can get a production output of about 10,000 to 12,000 per hour from the machine. This is an expensive method and it can be used to manufacture different types of cement bricks using a variety of raw materials. The machinery used in this plant or factory needs the following:

- An interactive user interface

- Security configuration logic control

- A fault diagnosis display

- PLC automatic control systems

- Control system

- Production procedures

The price of a fully- automatic cement brick-making machine ranges from Rs. 2,50,000 to Rs. 5, 00,000.

How to promote my cement bricks business

You can contact many of the cement brick manufacturers to get the orders, where you can get all the information about the manufacturers in ‘Cement Brick – IndiaMART Business Directory’. From there you can get good contacts for your business and slowly you can expand your business idea, after earning good profits.

The conclusion to start and make money from cement brick manufacturing

Thus, we can conclude that in the construction field, the cement concrete cement brick manufacturing business is an ideal business plan to start on a small scale. If you have an open area in your house of 300 sq. meters then you can start the business at your home as it reduces the investment of your business. I hope this blog has given you all the information required to design a perfect concrete block manufacturing business plan.

In case if you are interested in this: Organic Vegetable Farming Plan.

- Handicraft Making at Home: A Small Profitable Business Idea

- Pet-Tech Startups: Innovations for Animal Lovers

- Tech Repair Services: Meeting the Demand for Gadget Maintenance

- Maximizing Rewards: Smart Credit Card Habits for Cashback and Points

- Ultimate Guide to Making Money from Goat Milk Business

- How to Start an Agricultural Value Added Product Business

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

- How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

- 10 Value-added Business Ideas for Millets: Low-investment and Highly Profitable

- Why Cleaning Service Business Becoming More Profitable in Metro Cities in India

- 10 Best Businesses to Start in Ayodhya for Profits

- Top Drone Business Ideas in India: Unlocking Aerial Innovation & Opportunities

- Top 10 Service Businesses You Can Start with No Money

- Ultimate Guide to Starting a Home-Based Advertising Agency Business

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

- Construction Company Name Ideas: Guide to Create New Construction Company Names

- 8 Best Small Businesses to Start in Hyderabad: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Massachusetts: Low-Cost and Profitable

Hi, good information regarding cement brick mfg business.if you could also suggest about raising capital for this project it will be very helpful.i am planning to commence a unit in rural Andhra Pradesh some 150 Kms from chittoor

Good information

I am planning to start the same business and it’s very helpful information for me

Thanks a lot

Fantastic article and honestly saying it really helped me to conduct my own analysis.

I really appreciate that you shared this amazing post with us, thanks for sharing and keep up the amazing work.