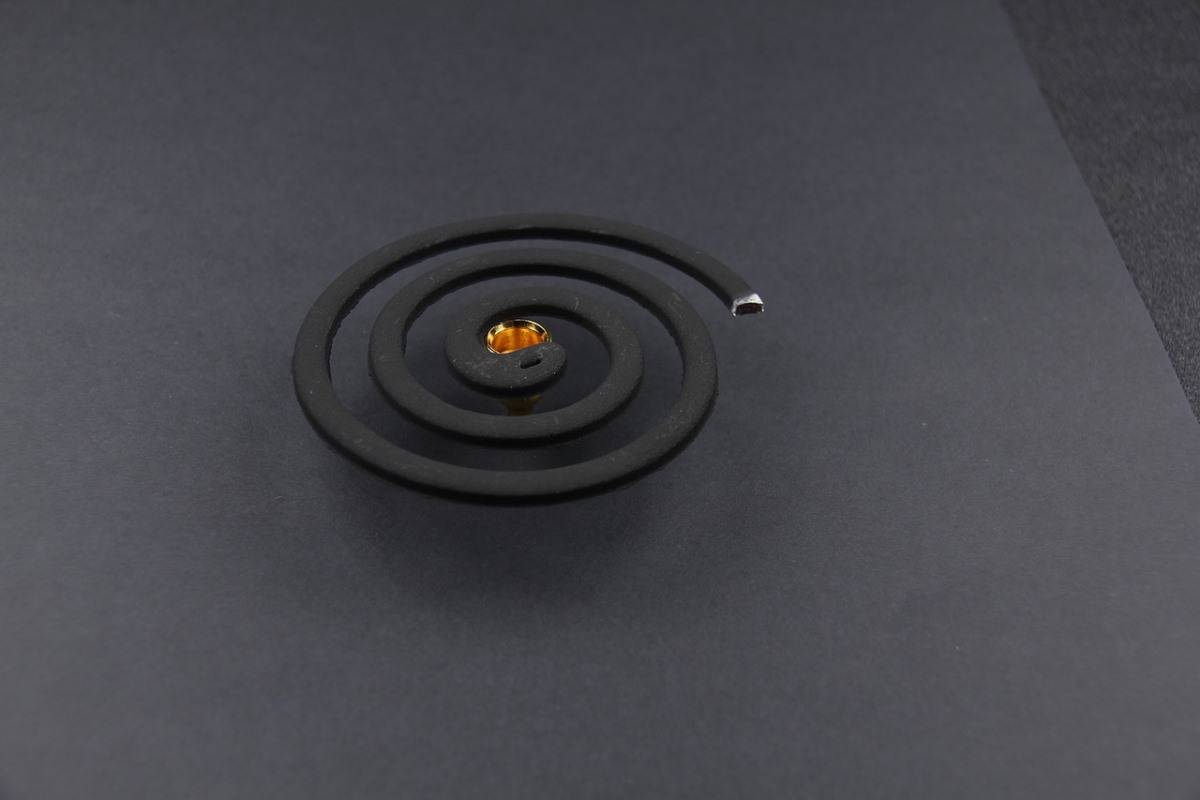

Introduction to Mosquito Coil Project Report, Manufacturing Process Business Plan: Hello folks, today we are here with a new topic called “Mosquito Coil Project Report”. Mosquitoes suck human blood for their own need but indirectly they are spreading deadly diseases like dengue, malaria, etc. Mosquito coil has been used for years as repelling element and killing of insects including flies, mosquitoes, etc. It saves people from mosquitoes by no direct contact with human bodies. It has high demand in India and the International market. The competition in this segment is very narrow and the supply is regularly needed. As it has huge demand, so there is a good possibility for budding entrepreneurs to tap the market and gain profits.

Mosquito Coil Project Report, Manufacturing Process Business Plan

The financial analysis of a project report is based on the following segments.

- Market potential

- Basis and presumptions

- Implementation schedule

- List of approvals required

- Raw materials required

- List of machinery and equipment

- Manufacturing process

- Project economics

- Profitability

Market potential of Mosquito Coils Manufacturing Business

The market demand for coil stands has been growing every day and is almost equally in demand with the Mosquito coils in the market. There is an ever-growing need for the coil to prevent mosquito-borne infections and the spread of diseases. Especially, during the rainy seasons, a lot of water gets stagnated in unused tires, holes, pots, dustbins, and any other things which are not in use on regular basis. They serve the best regions for breeding mosquitoes as humidity is the best environmental condition. This indicates the ever-growing demand for these types of the coil along with their stands in the market.

Basic and presumptions of Mosquito Coils Manufacturing Business

- Working hours/shift: 8 hrs.

- No. of shift/day:1

- Working days: 300

- Labor expenses: as per the State Government’s Minimum Wages Act.

- Rate of interest: 15% per annum

- Costs of machinery and equipment: Taken based on a particular dealer

- Value of raw material: As per local market Packing material/others rate (on wholesale rate)

- Land: owned

- Building Construction

- Break-even point will be estimated on a full capacity utilization basis

- Pay-back time is 5 – 7 years

Implementation Schedule of Mosquito Coils Manufacturing Business

- Preparation of project report 2 weeks

- Selection of Site 2 weeks

- Provisional registration as small-scale unit 1 week

- Availability of loan finance 4 weeks

- Procurement of machinery and Equipment 4 weeks

- Erection of Machinery and Equipment 1 week

- Recruitment of staff and labor 2 weeks

- Procurement of raw material 2 weeks

- Trial production 2 weeks

The overall time required to start the project is 4 to 5 months.

List of approvals required for starting Mosquito Coil Manufacturing Business

Below is the list of licenses, registration, and permissions required to start a Mosquito Coil Manufacturing Business:

- MSME registration

- GST registration

- ROC

- Registration of firm

- Shop Act License

- IEC Code

- Export License

- Fire and Safety

- ESI

- PF

- NOC: No Objection Certificate from pollution board

- Trade license from local municipal authority

Area required to start Mosquito Coil Manufacturing Business

To start a small-scale Mosquito Coil Manufacturing Business, you require 300 – 500 sq. mt of area.

The raw material required for starting Mosquito Coil Manufacturing Business

The raw material needed for this manufacturing process is available easily. These plates are bought from popular suppliers and then processed on a shearing machine that helps to cut in size and later they are sent to the power press.

Quality Control & Standards: Though there are no such hard and fast specifications, the product is manufactured in the range of 78mm (length) x 45mm (width).

List of machinery required to start Mosquito Coil Manufacturing Business

Below is the list of machinery required to start Mosquito Coil Manufacturing Business –

- Shearing machine

- Power press 20 Tons

- Die with Auto feeder

- Machine drivers

- Measuring instruments

Mosquito Coils Manufacturing Business

Pollution control: The manufacturing process does not involve the release of any kind of pollutants and hence there is no need to consider any pollution measures.

Energy Conservation: The entire manufacturing does not use much power and there is no such obligation to restrict the usage. However, it is recommended to service the machines from time to time to maintain them properly and use the power when required and minimize the over usage in the unit.

Mosquito Coil Project Report/Economics of Mosquito Coils Manufacturing Business in India

In case if you miss this: Clove Oil Manufacturing Project Report.

A. Fixed capital Per month (Rs)

(i) Land & building

Rented 250 sq m area (workshop, office & store) Rs. 10,000 per month

(ii)Machines and Equipment

Shearing machine Rs. 74,000

Power press 20 Tons Rs. 1,10,000

Die with Auto feeder Rs. 35,000

Machine drivers Rs. 2,500

Measuring instruments Rs. 10,000.

Office furniture Equipment

Electrification and installation @10 of total cost of machinery: Rs. 18,400

Total Rs. 2,49,900

Say Rs. 2,50,000.

iii) Pre operative Cost Rs. 20,000

Total fixed capital (ii) + (iii) Rs. 2,70,000

B. Working Capital (per month)

Manager /Engineer: Rs. 12000

Skilled Worker-2: Rs. 12000

Semi Skilled Worker-2: Rs. 10000

Peon Cum Watchman-1: Rs. 5000

Sweeper (part time)-1: Rs. 2000

Helper-1: Rs. 4500

Total: Rs. 45500

Perquisites@ 20%: Rs. 9100

Total: Rs. 54,600

Say: Rs. 55,000.

Raw material

Tin plate 60000/ton 04 tons: Rs. 2,40,000

Packing material: Rs. 10,000

(iii) Utilities

Power: Rs. 2500

Water: Rs. 500

(iv) Other Contingent Expenses

Rent: Rs. 10,000

Postage & Stationery: Rs. 500

Repair & maintenance: Rs. 3,500

Transport & conveyance: Rs. 5,000

Telephone Charges: Rs. 500

Insurance: Rs. 1,500

Miscellaneus Expenses: Rs. 1,000

Total: Rs. 22,000

(v) Total Recurring Expenses (pm)

Raw material 2,50,000

Personal 55,000

Utilities 3,000

Other contingent Expenses 22,000

Total: Rs. 3,30,000

Total capital Investment

Fixed Capital: Rs. 2,70,000

Working Capital (for 3 months): Rs. 9,90,000

Total: Rs. 12,60,000.

Financial Analysis

(1) Cost of production (per year) in (Rs)

a) Total recurring cost: Rs. 39,60,000

b) Depreciation on Tools and office Equipment @ 20%: Rs. 9,500

c) Depreciation on machinery @ 10%: Rs. 18,400

d) Interest on total investment @ 12.5%: Rs. 1,57,500

Total: Rs. 41,45,400.

Turnover

(2) Total Sales (per annum)

By sale of 90,00000 @ 0.52 each = Rs. 46,80,000

(3) Profit (per year)

Profit = (Total sale) – (Cost of production)

= Rs.46,80,000 – Rs.41,45,400

= Rs.5,34,600.

(4) Net profit ratio = Net profit per year x100

Turn over per year = 5,34,600/ 46,80,000 x 100 =11.4%

Rate of Return = Net profit per year x100

Total investment = 5,34,600/ 12,60,000 x100 = 42.4%.

Break even point

Rent: Rs. 1,20,000.

Depreciation on Machinery @10%: Rs. 18,400

Depreciation on Tools & office Equipment @20%: Rs. 9,500

Interest on Loan: Rs. 1,57, 500

40% of Salary & Wages: Rs. 2,64,000

40% of other Contingent Expenses: Rs. 57,600

40% of Utilities: Rs. 14,400

Total: Rs. 6,41,400

B.E.P. = Fixed Cost x 100/Fixed Cost + profit

= 6,41,400 x 100/11,76,000 = 54.5%.

- Handicraft Making at Home: A Small Profitable Business Idea

- Pet-Tech Startups: Innovations for Animal Lovers

- Tech Repair Services: Meeting the Demand for Gadget Maintenance

- Maximizing Rewards: Smart Credit Card Habits for Cashback and Points

- Ultimate Guide to Making Money from Goat Milk Business

- How to Start an Agricultural Value Added Product Business

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

- How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

- 10 Value-added Business Ideas for Millets: Low-investment and Highly Profitable

- Why Cleaning Service Business Becoming More Profitable in Metro Cities in India

- 10 Best Businesses to Start in Ayodhya for Profits

- Top Drone Business Ideas in India: Unlocking Aerial Innovation & Opportunities

- Top 10 Service Businesses You Can Start with No Money

- Ultimate Guide to Starting a Home-Based Advertising Agency Business

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

- Construction Company Name Ideas: Guide to Create New Construction Company Names

- 8 Best Small Businesses to Start in Hyderabad: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Massachusetts: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Maryland: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Delaware: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Connecticut: Low-Investment and Profitable

- Top 10 Best Online Pet Business Ideas: Exploring Cats to Dogs

- 10 Best Small Businesses to Start in Colorado: Low-Investment and Profitable

- Top 10 Profitable Small Business Ideas in California: Low-Investment Tips

- From Little Rock to Fayetteville: Top 10 Profitable Small Business Ideas in Arkansas

- Top 10 Profitable Small Business Ideas in Alabama: Discover Opportunities in Alabama’s Growing Cities

- Top 10 Profitable Small Business Ideas in Arizona: Discover Opportunities in Arizona’s Growing Cities

- Golf Business Ideas: Exploring Golf Course Money Making Ideas

- Low Capital Profitable Small Farm Ideas: Farming Ideas to Make Money

- How to Write a Business Plan for Daycare: Exploring from Financial Projections to Risk Management

- Home Daycare License Requirements: Exploring State-wise In-home Daycare Requirements

- How Profitable is Day Care Business: How Much Does a Daycare Owner Make a Month or Year?

- How to Open a Daycare Center in Toronto, Canada: Business Plan, Licenses and Permits