Introduction to Tamarind Paste Project Report, Manufacturing Business Plan: This blog comprises a detailed sample business project about initiating a tamarind paste-making business. Besides, the article will focus on tamarind paste-making ingredients, machinery, market potential, manufacturing process, project finances, and profits.

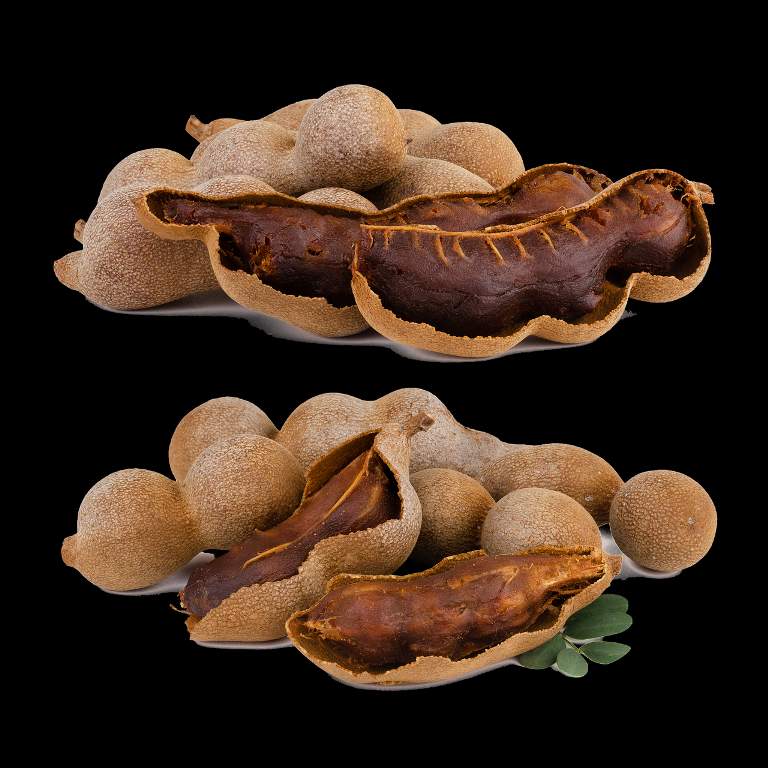

Tamarind pulp is an edible product; thus, people consume tamarind pulp while preparing several recipes. Also, it is having the demand as a pickling agent because of its sour taste.

Tamarind paste has several culinary applications as sad previously which includes a flavoring agent in curries, chutneys, and the commonly used sharbat syrup drink. The tamarind sweet chutney is well-known in India and Pakistan used as a garnishing item for few snacks. This tamarind pulp includes 20% moisture, almost 6% fiber, and high carbohydrates percentage (about 67 %).

However, tamarind pulp is having perishable nature and cannot be stored for long. Because of this, people are eager to purchase packaged tamarind paste for their daily cooking necessities. Also, the paste is used with ease and is not so problematic as raw tamarind. That is the main cause for the popularity of tamarind paste and its demand in urban and rural regions.

A guide to Tamarind Paste Project Report, Tamarind Manufacturing Process, and Business Plan

When you have all the necessary data about the market, the next step is designing your business plan for the Tamarind Paste-making business. Yes, there are several businesses plans available online for crafting your plan using different software. Even they are effective indeed. But if they are not helpful, it’s suggested to refer a professional.

Commonly, a business plan comprises two primary segments. The major one is the technical aspect followed by the financial analysis. The financial scheming depends on technical features. It’s also essential to consider your budget constraints while considering the technical aspects.

Business plan for starting Tamarind Paste Manufacturing

You need to concentrate on crafting a perfect business plan for starting Tamarind Paste Manufacturing Business which includes:

- Market potential for Tamarind Paste Manufacturing Business

- Implementation schedule of Tamarind Paste Manufacturing Business

- Basis and Presumptions of Tamarind Paste Manufacturing Business

- List of approvals required for Tamarind Paste Manufacturing Business

- Area required for Tamarind Paste Manufacturing Business Unit

- Raw materials required for Tamarind Paste Manufacturing Business

- List of machinery required for Tamarind Paste Manufacturing Business

- Manufacturing process of Tamarind Paste

- Project economics of Tamarind Paste Manufacturing Business in India

- Profitability in Tamarind Paste Manufacturing Business

Market potential of Tamarind Paste Manufacturing Business

This is the main step while planning for any food processing-related business. One must figure out the precise market for your definite product. Tamarind paste is a fast-selling readymade product consumed for cooking. Thus, the primary focus should be on the grocery stores, departmental stores, or supermarkets, and self-service counters are even the perfect zones to sell your product. In the present era, online marketplaces and food delivery possibilities are preferred as well. Not only this, it has a decent demand in countries such as the USA, UAE, and Malaysia.

Basis and Presumptions of Tamarind Paste Manufacturing Business

The Tamarind Paste Manufacturing project profile relies on the following assessments:

- Working hours/shift: 8 hrs.

- No. of shift/day:1

- Working days: 300

- Labor expenses: According to State Government’s Minimum Wages Act.

- Rate of interest: 15% per annum

- Costs of machinery and equipment: Taken based on A particular dealer

- Value of raw material: As per local market Packing material/others rate (on wholesale rate)

- Land: owned

- Building Construction charge: About Rs. 2000 per sq. ft.

- Break-even point will be estimated on a full capacity utilization basis

- Pay-back time is 5 – 7 years

Implementation schedule of Tamarind Paste Manufacturing Business

- Market analysis and demand, applying for loan 0 – 1 month

- Preparation of business plan 1 – 2 months

- Financial support or investment 2– 4 months

- Selection of location and establishment of unit 3 – 4 months

- Power and water connection facility: 4 – 5 months

- Building construction and shed development 5 – 6 months

- Machinery and equipment purchase 6 – 7 months

- Procuring raw materials and recruiting of manpower 8 – 9 months

- Trial operations 10th month

List of approvals and permits required to start Tamarind Paste Manufacturing Business

The next step to start Tamarind Paste Manufacturing Business in India is acquiring the following list of licenses, permissions and registrations –

- Register your business identity

- MSME registration

- GST registration

- ROC

- Get the PAN Card

- Registration of firm

- Shop Act License

- FSSAI License

- IEC Code

- Export License

- Fire and Safety

- ESI

- PF

- No Objection Certificate from pollution board

- Trade license from local municipal authority

Note: These approvals may vary based on the area you would like to start the business.

Area required to start Tamarind Paste Manufacturing Business

Around 800 sq. ft. area that is preferably an industrial region is sufficient to begin a small-scale unit. The area must include water and power facilities. Next, for the unloading and loading, it is essential to keep a wide entrance.

After identifying the space, it is important to accommodate machinery and stick to your prepared floor plan. Allot particular areas for the storage, testing lab, production, packaging, and official work. You can even check with some of the machinery providing company to aid you in this regard.

Manpower required for Tamarind Paste Manufacturing Business

For establishing a small-scale factory, one can operate with about 6 employees. However, the number of workers depends on the unit size and production output. Generally, the workers necessary for specific operations are stated below

- Production manager or the chemist – 1

- Skilled workers – 2

- Semi-skilled workers – 2

- Administrative employees– 1

Raw materials required for Tamarind Paste Manufacturing Business

In case if you miss this: Aloe Vera Gel Manufacturing Project Report.

The main component for the business of tamarind paste making is raw tamarind. Apart from that, one must get Class II preservatives. Packaging is possible by the glass or plastic bottles. Besides, you have to get hard cardboard outer cartoons and straps when planned for bulk packing. Lastly, you will need printed labels for including product information to the people.

Machinery required for starting Tamarind Paste Manufacturing Business

The unit can be established either in a fully- automatic way or semi-automatic manner. The semi-automatic unit is suggested in the initial stages for budding entrepreneurs. Some of the key obligatory machineries are stated below:

- Baby boiler and accessories

- Stainless steel pulp extractor

- Stainless steel steam jacketed kettle

- Motor, Stirrer, and reduction gears for the kettle

- Cup washing and drying machine

- Stainless steel working tables

- Lab equipment

Process of Manufacturing Tamarind Paste

The first step in the Tamarind paste-making business is to de-seed the raw tamarind. Next, one has to take small quantities of water to soak the tamarind in the kettle. Now, this mass will be heated carefully till pulp becomes soft. Agitate the mass and remove it from the kettle. And now, the pulp will be extracted with an extractor.

The pulp obtained is once again added into the kettle to make it concentrated and it becomes two-thirds its volume. 1 Kg of tamarind will provide 400 grams of the paste. Next, add the preservatives to pack the product in different volumes containers and will be sealed.

Tamarind Paste Project Report/Economics of Tamarind Paste Manufacturing Business in India

Fixed Capital

a. Land and Building: 600 Sq ft @ Rs. 10,000 Rented

b. Machinery and Equipment: Rs. 4,25,000.

Working Capital

A. Staff and Labor: Rs. 1,72,000

B. Raw material per month: Rs. 1,76,675

C. Utilities per month: Rs. 8,000

D. Other Contingent Expenses per Month: Rs. 1,75,000

Total Working Capital per month = A + B + C + D = 1,72,000 + 1,76,675 + 8,000 + 1,75,000 = Rs.

5,31,675.

Total Capital Investment

Fixed capital = Rs. 4,25,000

Working Capital (on 3 months basis) = Rs. 15,95,025

Total = Rs. 20,20,025.

Financial analysis of Tamarind Paste Manufacturing business

a. Cost of Production (Per Year): Rs. 66,24,603

b. Turnover (Per Annum): Rs. 72,00,000

c. Net Profit Per Annum:

Net Profit = Turnover per Year – Cost of Production = Rs. 72,00,000 – Rs. 66,24,603 = Rs. 5,75,397

d. Net Profit Ratio = (Net Profit per year / Turnover per Year) X 100 = (5,75,397 / 72,00,000) X 100 =

7%.

e. Rate of Return = (Net Profit per year / Total Investment) X 100 = (575397 / 2020025) X 100 =

28.48%.

Break-Even Point (B.E.P.)

Interest on investment @ 10%: Rs. 2,02,003

40% of wages and salaries: Rs. 68,800

40% of other expenses (except rent): Rs. 70,000

Rent: Rs. 1,20,000

Total: Rs. 4,60,803

Break- Even Point (B.E.P.) = [Fixed Cost/ (Fixed cost + Profit)] X 100 = 460803/ (460803+575397) X

100 = 4,60,803 / 10,36,200 X 100 = 44.47%.

- Handicraft Making at Home: A Small Profitable Business Idea

- Pet-Tech Startups: Innovations for Animal Lovers

- Tech Repair Services: Meeting the Demand for Gadget Maintenance

- Maximizing Rewards: Smart Credit Card Habits for Cashback and Points

- Ultimate Guide to Making Money from Goat Milk Business

- How to Start an Agricultural Value Added Product Business

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

- How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

- 10 Value-added Business Ideas for Millets: Low-investment and Highly Profitable

- Why Cleaning Service Business Becoming More Profitable in Metro Cities in India

- 10 Best Businesses to Start in Ayodhya for Profits

- Top Drone Business Ideas in India: Unlocking Aerial Innovation & Opportunities

- Top 10 Service Businesses You Can Start with No Money

- Ultimate Guide to Starting a Home-Based Advertising Agency Business

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

- Construction Company Name Ideas: Guide to Create New Construction Company Names

- 8 Best Small Businesses to Start in Hyderabad: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Massachusetts: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Maryland: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Delaware: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Connecticut: Low-Investment and Profitable

- Top 10 Best Online Pet Business Ideas: Exploring Cats to Dogs

- 10 Best Small Businesses to Start in Colorado: Low-Investment and Profitable

- Top 10 Profitable Small Business Ideas in California: Low-Investment Tips

- From Little Rock to Fayetteville: Top 10 Profitable Small Business Ideas in Arkansas

- Top 10 Profitable Small Business Ideas in Alabama: Discover Opportunities in Alabama’s Growing Cities

- Top 10 Profitable Small Business Ideas in Arizona: Discover Opportunities in Arizona’s Growing Cities

- Golf Business Ideas: Exploring Golf Course Money Making Ideas

- Low Capital Profitable Small Farm Ideas: Farming Ideas to Make Money

- How to Write a Business Plan for Daycare: Exploring from Financial Projections to Risk Management

- Home Daycare License Requirements: Exploring State-wise In-home Daycare Requirements

- How Profitable is Day Care Business: How Much Does a Daycare Owner Make a Month or Year?

- How to Open a Daycare Center in Toronto, Canada: Business Plan, Licenses and Permits