Puffed rice has a constant demand over time and year-round. All the people eat it with great excitement, no matter how rich or poor they are. It has also been utilized as an offering to God. A small amount of cash is required to get this venture off the ground. When starting a business, the government will also lend you money if you don’t have the money. Let’s check out how to make money from Puffed Rice.

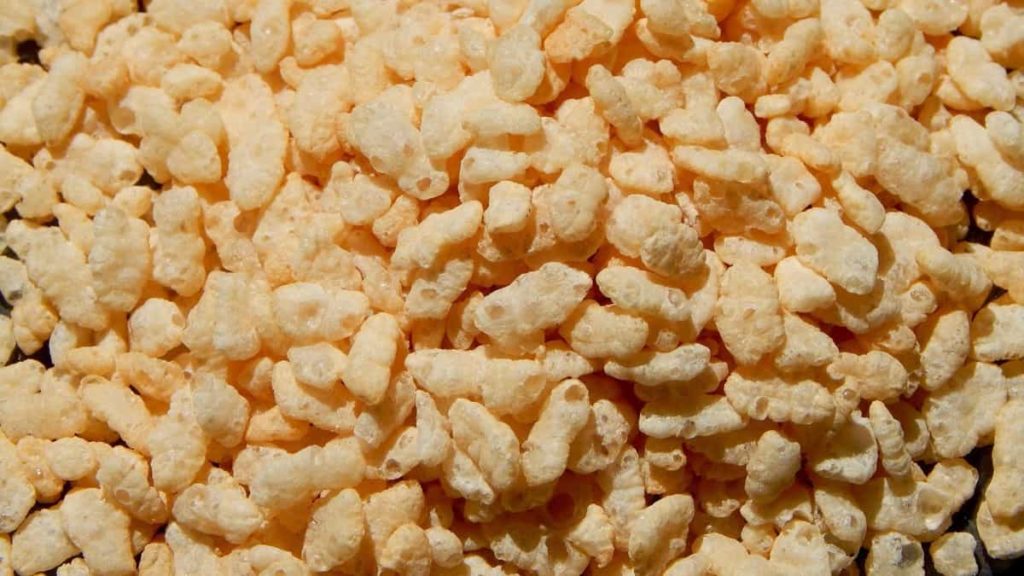

Puffed rice, often known as murmura (Murmured), is a popular fast food in India. City or village, its usage is widespread.” Every region in the nation makes use of it in some way. Street food vendors are increasingly serving it. Bhelpuri in Mumbai till Jhalmudi in Kolkata in puffed rice is everywhere. There are temples and sacred places where it is served as an offering. Today, murmur’s popularity has skyrocketed.

Large shopping malls also sell it. However, it’s offered in a more visually appealing package in larger retail outlets. Making puffed rice could be a preferable option in this situation. There are several ways to make money in this line of work when demand is low. When heated in an oven loaded with sand, rice is transformed into puffed rice, called muri. It’s easy to puff up rice, which the Hindi language refers to variously as “kurmura,” “murmura,” and “muri.”

Rice is used to make puffed rice, and the high-pressure heating expands the rice grains. It takes a lot of time and cares to prevent the rice grains from burning while roasting in a large iron Kadai. If you eat the same quantity of puffed rice as plain rice, you’ll absorb fewer calories. It is used in bhelpuri and other famous char recipes.

Puffed Rice market in India

Bhel puri, a savory snack in India and a form of chaat, is the most common sight nowadays. In addition to its cost, RTE (ready-to-eat), and lightness, puffed rice has become a popular snack and morning cereal in many countries throughout the globe. However, even though India is the world’s second-largest producer of rice, its value-added rice products, including puffed rice, popped rice, and flaked rice, account for barely 10% of its yearly production. Nevertheless, puffed rice is in great demand in domestic and foreign markets.

Puffed rice exporters are concerned about consistent puffing, contamination-free production, pleasing color, texture, etc. There is currently no puffed rice manufacturing outside of rural areas in India. The puffing process is time-consuming and requires many highly-skilled labors in extremely hot weather. Farmers are raising more rice to suit the rising demand for muri. One may use extrusion, high pressure, or these three methods in puffing food.

For this reason, when seeds are expanded in the puffing process, high-pressure vapour pressure escapes from the grain structure through micropores. Dry heat, sand and salt, hot air popping and gun puffing are just a few of the numerous types of puffing.

In case you missed it: How to Start a Packers and Movers Business in India?

How to make money from Puffed Rice: Steps

Make a Murmura/Puffed Rice business plan

For starting any business, you have to prepare a business plan first. The puffed rice business is one of the businesses with consistent demand, and to start this business, you need to prepare yourself first. For this, you must estimate every parameter involved in the business, like staff requirements, area requirements, and investment requirements. The business plan should also express the proper execution of how your business will run. You can refer to your business plan each time you feel that you are sliding apart from the actual business or for any doubts about how your business will run.

Select an appropriate location

You should be very careful when choosing an appropriate location for your puffed mill. Make sure it is an ideal one for establishing your puffed mill business. There are two ways to start your puffed rice business. First, if you have enough space in your home, you can start a puffed rice business on a small scale.

The area required for this will be less, but if you are going to establish a large-scale puffed rice industry, you need a minimum of 1000 square meters of space. In addition, you need to have space for a sufficient storage facility too. By keeping all these factors in mind, you should choose the location where you want to establish your puffed rice mill.

In case you missed it: How to Start a Homecare Service Business for Elderly in India?

Puffed Rice/Murmura mill investment and project cost

For a small-scale puffed rice mill established at home, there is only machinery cost that too only small equipment will be used which can be operated and controlled by a single person which excludes the labor cost. At most, a small-scale puffed rice mill costs nearly Rs. 1,00,000, including miscellaneous costs.

According to the Khadi and Village Industries Commission’s project profile report, starting a puffed rice business requires owning your property. Renting land is an option for those who lack their own. A 1000 square foot building shed will cost Rs 3,00,000 to construct. Equipment will also cost Rs. 5,00,000 at the same time. It would also need a working capital of Rs 1,00,000. It has now risen to Rs 9,00,000 in total cost.

Licence and registration for your Puffed Rice mill

Business Registration: It is clear that registering a legal organization in India is the first stage. The business owners might choose from one of the following business models depending on the scope of activity and capital investment: Limited Liability Partnership (LLP), Private Limited Liability Company (PLC), and Public Limited Liability Company (PLC)

Factory license: Each state’s local government often issues a factory license. Under the Factory Act, a license of this kind is required. To apply for a factory license online, applicants must provide the needed papers relevant to the business’s site plan and business strategy.

Pollution control certificate: Water (Prevention and Control of Pollution) Act, 1974 states that every business owner who operates a facility that releases pollutants into water resources or the surrounding area must first get permission from their local pollution control board and submit an application to that board.

Before establishing any industry or business, the State Pollution Board issues a “No Objection Certificate” (CTE). In addition, a business or process facility can quickly obtain a Consent to Operate No Objection Certificate (CTO) after being established. Renewals are required for No Objection Certificates. Keep in mind that each state’s pollution control board has its website via which applicants may submit CTE and CTO applications.

In case you missed it: Top 15 Franchise Businesses in India

FSSAI License: Anyone in the food industry, including rice growers, must obtain a Food Safety and Standards Authority of India certification. To apply for an FSSAI license, you must submit an online application and a stipulated fee to your local government website. In addition, the candidate will be requested to submit the following essential papers throughout the application process.

GST registration: Businesses who want to sell beyond state lines must get a GST number. There is an online form to register for GST at the official website. The applicant must submit the necessary fundamental papers throughout the form submission process.

Puffed rice raw materials

Rice, salt, LPG/wood, and fuel are the basic raw materials used in this manufacturing process.

The machinery required for puffed rice processing

Paddy destoner: Destoners for paddy are machines that remove stones, sand, and other impurities from the grains before they are collected. A paddy destoner machine, also known as a rice destoner, is essential for puffed rice processing.

Cost: Rs. 1,50,000 per unit for 3 HP paddy destoner

Puffing machine: Puffed rice, rice flakes, and other cereal grain-based items can be made using a buffing machine. You can call it a puffed rice-making machine.

Cost: Rs. 1,10,000 per unit for 3 HP Puffing machine

Storage silos: A silo is a bulk material storage structure. Hay can be stored in silos. Grain and food goods are more typically stored in silos. Silos can be divided into three general categories: tower, bunker, bag, and silage piles.

Cost: Rs. 25,000 per unit

In case you missed it: How to Make Money From 3D Printing: Small Business Tips for Beginners

Weighing scales: Weighing scales measure the weight of the puffed rice produced per batch. It is used to measure the amount of yield of your mill.

Cost: Rs. 20,000 per unit

Packing machines: Packing machines are the machines that are used to pack the puffed rice yield in your factory into small sellable packets before sending them to the market.

Cost: Rs. 1,00,000 per unit

These machines are essential for starting a puffed rice mill. However, most of these machines can cost lakhs. So be careful while choosing the machinery, as it can directly impact the yield of your puffed rice mill.

The processing of Puffed Rice

- The husk and stones from the rice are first removed.

- Then, a brine solution is used to soak it, and it’s dried. After drying, the product is sent into the puffing machine, where it produces the two puffed products. To avoid moisture absorption, it is cooled and packaged quickly.

- When heated in an oven loaded with sand, rice is transformed into puffed rice, known as muri.

- Rice is less prone to spoilage because of the processing involved.

- When cooked inside the grain’s shell, starch and moisture react to generate puffed rice. In contrast to popcorn, Rice kernels are devoid of moisture by nature and must be pre-conditioned using steam. Puffed rice can be made by two methods: You can cook the steam-conditioned kernels with oil or in an oven.

- Crisped rice is the rice that has been puffed in this manner. In the production of Rice Krispies cereal and the crisped rice used in Lion Bars, Nestle Crunch, Krackel, and other chocolate bars, oven-crisped rice is used. The change is less dramatic than popcorn, but the procedure and outcome are the same.

- Rice can also be puffed using a “gun puffing” technique, in which the grain is moistened to the appropriate amount and then pressured to 200 psi (1,400 kPa). Grains puffed out when a rapid release of pressure was applied to them.

- The puffed rice that results from this process has a spongy feel. Extruding little pellets of rice dough and then quickly heating them is another method of puffing rice. The rice puffs up because of the rapid boiling of the water in the dough.

Hire the staff for your puffed rice mill

It would help if you had staff to run this business on a large scale. You need laborers, supervisors, and a manager for your mill for running this business. You need at least 2 to 3 unskilled laborers, two skilled laborers to take care of machines, a supervisor to manage them, and a manager to take care of your mill. Of course, you can fill yourself in the manager post if you are good at managing people. As a manager, you also have to keep an eye on market demand and transport fluctuations and keep a regular touch with traders and distributors.

Packing

Polythene bags of 1 kilogram, 2 kilograms, and 5 kilograms of muri or puffed rice are sold in 1 kilogram, 2 kilogram, and 5-kilogram polythene bags and are bundled into large bags of 20 to 30 kilograms. Your company’s name and pricing are then printed on the packet’s cover. And it’s now time to put it on the market for sale.

In case you missed it: How to Start a Bowling Alley Business In India

Profit margin

As you are a puffed rice manufacturer, you need to find a trader or a distributor, which will not be that hard. Because puffed rice is such a common choice, the profit margins in the manufacturing industry are very large. This is because the market price of puffed rice is twice as high as the entire cost. But paddy costs about Rs 14 to 17 per kg, producing 1-kilo murmura costs around Rs 5, while puffed rice per kg you sell is Rs 35 to 40 in the market. In this case, the retail profit margin is almost doubled, but you can sell it in the market for Rs 5 per kg wholesale profit. As a result, profit can be calculated based on your costs; all you need is patience.

- Handicraft Making at Home: A Small Profitable Business Idea

- Pet-Tech Startups: Innovations for Animal Lovers

- Tech Repair Services: Meeting the Demand for Gadget Maintenance

- Maximizing Rewards: Smart Credit Card Habits for Cashback and Points

- Ultimate Guide to Making Money from Goat Milk Business

- How to Start an Agricultural Value Added Product Business

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

- How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

- 10 Value-added Business Ideas for Millets: Low-investment and Highly Profitable

- Why Cleaning Service Business Becoming More Profitable in Metro Cities in India

- 10 Best Businesses to Start in Ayodhya for Profits

- Top Drone Business Ideas in India: Unlocking Aerial Innovation & Opportunities

- Top 10 Service Businesses You Can Start with No Money

- Ultimate Guide to Starting a Home-Based Advertising Agency Business

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

- Construction Company Name Ideas: Guide to Create New Construction Company Names

- 8 Best Small Businesses to Start in Hyderabad: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Massachusetts: Low-Cost and Profitable

- 10 Best Small Businesses to Start in Maryland: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Delaware: Low-Investment and Profitable

- 10 Best Small Businesses to Start in Connecticut: Low-Investment and Profitable

- Top 10 Best Online Pet Business Ideas: Exploring Cats to Dogs

- 10 Best Small Businesses to Start in Colorado: Low-Investment and Profitable

- Top 10 Profitable Small Business Ideas in California: Low-Investment Tips

- From Little Rock to Fayetteville: Top 10 Profitable Small Business Ideas in Arkansas

- Top 10 Profitable Small Business Ideas in Alabama: Discover Opportunities in Alabama’s Growing Cities

- Top 10 Profitable Small Business Ideas in Arizona: Discover Opportunities in Arizona’s Growing Cities

- Golf Business Ideas: Exploring Golf Course Money Making Ideas

- Low Capital Profitable Small Farm Ideas: Farming Ideas to Make Money

- How to Write a Business Plan for Daycare: Exploring from Financial Projections to Risk Management

- Home Daycare License Requirements: Exploring State-wise In-home Daycare Requirements

- How Profitable is Day Care Business: How Much Does a Daycare Owner Make a Month or Year?

- How to Open a Daycare Center in Toronto, Canada: Business Plan, Licenses and Permits

- How to Start Meal Prep and Delivery Services: A Popular Business Idea

- How to Start a Milk Chilling Plant Business

- How to Start Coconut Shell Charcoal Business: Business Plan for Maximizing Profits